Self-propelled machines

For all earthworks, KW Hydraulik has the right tools at your disposal. Discover our range for earthworks today.

- Products

- Hydraulic Pumps

- Cable crimping tools

- Cutting tools

- Busbar machining center

- PTO for small vehicles

- Punching tools

- Steel and bolt cutter

- Generators / Magnets / Welding

- Air compressors / Vacuum / Fans

- Water high pressure pumps

- Submersible pumps

- Self-propelled machines

- Drills / impact wrench / auger

- XLPE cable preparing

- Bending and straightening tools

- Demolition Shears

- Concrete crushers / pulverizers

- Breakers

- Pile driver / Vibratory plates / Vibration

- Angle Grinder / Grinder

- Pipe processing

- Diamond saws

- Chainsaws / pruning shears / log splitters / grabs

- Torque wrench

- Demolition and sorting grabs

- Pile cutter, pipe cutter, felling grapple

- Excavator buckets

- Cable winch

- Stroke cylinders

- Multi-Tools

- Remote controlled machines / robots

- Tools for meter mounting

- Solar Installation Tools

- Underwater Tools

- Tools for Railway Maintenance

- Fiber Optic Processing

HYDRA DRILLY

DRILLY – compact self-driving drilling machine HYDRA DRILLY

HYDRA DRILLY

This drill was developed to work in tight spaces DRILLY is delivered without a mounted hydraulic unit. It can be connected to aggregates or construction machines with a hydraulic outlet. A hydraulic unit can optionally be installed.Due to the distance to the unit, DRILLY can be used in hazardous environments or indoors. DRILLY can drill oblique and horizontal holes. The drill head can be rotated 360 ° Radio remote control optionally available

HYDRA-T

HYDRA Anbau-Erdbohrer HYDRA-T

HYDRA-T

Wir bieten eine große Auswahl an Modellen für Minibagger und Bagger von 120 bis 7800 kg. Jeder Kopf hat einen Stahlrahmen, eine Halterungsvorrichtung mit Kardangelenk zur Aufnahme am Bagger und Sechskantwelle für den Anschluss des Bohrers. Sie können zwischen Standarddurchmessern und Sondergrößen wählen. Die Bohrer sind für weiche oder felsige Böden lieferbar. Alle Bohrer bestehen aus einer doppelten Spirale und haben austauschbare Zähne. Für Felsboden in verstärkter Ausführung. Die Spiralbohrer können schnell mittels Sechskantanschluss verlängert werden. Durch die Kardanwelle kann die Montage horizontal erfolgen. Wir liefern auch Sonderausführungen die auf Führungen sowohl für horizontale als auch vertikale Bohrungen geeignet sind. Rechts-/Linkslauf optional lieferbar.

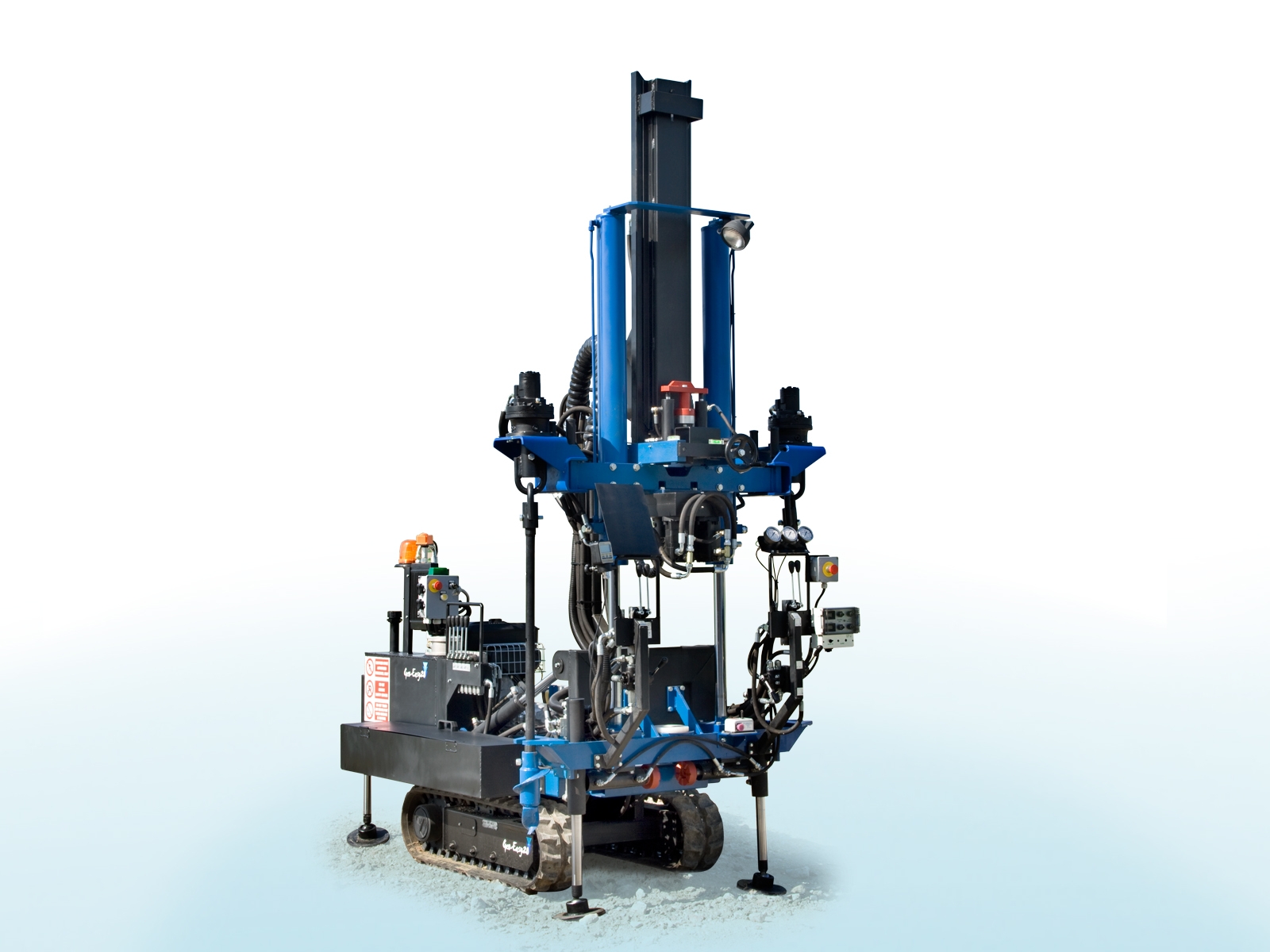

HYDRA GEO-EASY

HYDRA GEO-EASY - Self-Propelled Static / Dynamic Penetration Meter HYDRA GEO-EASY

HYDRA GEO-EASY

Static / dynamic penetrometer GEO-EASY-10 and GEO-EASY-20 for geotechnical testing and drilling with auger rod for sampling. These machines were developed to carry out geological sampling and investigations on soil. The most important aspects were user friendliness, easy transport due to small dimensions, versatile areas of application. Controllable at a distance with control panel. The standard equipment allows 4 types of samples to be carried out: Static tests up to 100 kN for GEO-EASY-10, 200 kN for GEO-EASY-20 Heavy dynamic tests Sampling and rotary drilling Sampling with a percussion drill Options: Semi-automated method with data collection piezocones Machine standard equipment: rotary head Static testing instrument Dynamic testing instrument 1 BEGEMANN drill bit 20 m bars for static tests 1 dynamic drill bit 20 m bars for dynamic tests 1 extension system for dynamic and static bars 2 lateral anchors 1 screw anchor pull system 2 hydraulic rotary heads for anchor operation 1 data display 1 tool box with wrench set

HH-JOY-3-G+SL400+HR55-HR40

HYDRA JOY3-GEO+SL400+HR55-HR40 - self-propelled vertical drilling rig HH-JOY-3-G+SL400+HR55-HR40

HH-JOY-3-G+SL400+HR55-HR40

Hydraulic drilling rig JOY-3-GEO+SL400+TR1200 Fully equipped for geothermal drilling Special model specially equipped for drilling boreholes in the field of geothermal energy (heat pumps).Furnishing:DOOSAN D34 diesel engine STAGE V with 100 kW Mount SL400 with 3600mm strokepressure and traction (each 10 tons) KRUPP HR55-HR40 double head drilling rigRotational movement of the tube: max. 50 revolutions per minute at 48,000 Nm, free passage 95 mmRotational movement of the rod: max. 220 revolutions per minute at 13,000 Nm, free passage 50 mm Fixing table for the horizontal displacement of the hydraulic rotary actuator radio remote control Triple pump 300 L/min at 50 bar Worm pump 1000 L/min at 20 bar Double clamp Ø205mm Movable on the mast, swiveling upper clamp (crushing cylinder) lower clamp, Shifting cylinder along the mast with 400 mm strokeWinch, 25 meter rope, 3000 kg lifting capacity 40 tubes Ø152x1500 mm (60 m)Crown for tubes Ø 152 mm External driver Ø 152 mm Internal driver Ø 90/152 mm (2"3/8api) 40 poles Ø 88.9x1500 mm (2"3/8api R.) (60 m)Down-the-hole hammer 5" (approx. 125 mm) Drill tip for down-the-hole-hammer This description is for guidance only. You cannot order this product online. The ordering process triggers only one request.

HH-JOY-3-G+SL400+TR1200

HYDRA JOY3-GEO+SL400+TR1200 - self-propelled vertical drilling rig HH-JOY-3-G+SL400+TR1200

HH-JOY-3-G+SL400+TR1200

Hydraulic drilling rig JOY-3-GEO+SL400+TR1200 Fully equipped for geothermal drilling Special model specially equipped for drilling boreholes in the field of geothermal energy (heat pumps).Furnishing:DOOSAN D34 diesel engine STAGE V with 100 kW Mount SL400 with 3600mm strokepressure and traction (each 10 tons) TR1200 hydraulic drill head 30-600 rpm Fixing table for the horizontal displacement of the hydraulic rotary actuator radio remote control Triple pump 300 L/min at 50 bar Worm pump 1000 L/min at 20 bar Double clamp Ø205mm Movable on the mast, swiveling upper clamp (crushing cylinder) lower clamp, Shifting cylinder along the mast with 400 mm strokeWinch, 25 meter rope, 3000 kg lifting capacity 40 tubes Ø152x1500 mm (60 m)Crown for tubes Ø 152 mm External driver Ø 152 mm Internal driver Ø 90/152 mm (2"3/8api) 40 poles Ø 88.9x1500 mm (2"3/8api R.) (60 m)Down-the-hole hammer 5" (approx. 125 mm) Drill tip for down-the-hole-hammer This description is for guidance only. You cannot order this product online. The ordering process triggers only one request.

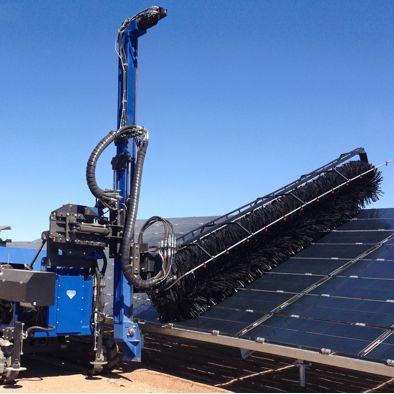

HYDRA SETYS

HYDRA SETYS - Solaranlagenreiniger - Panelenreiniger HYDRA SETYS

HYDRA SETYS

Aus der Erfahrung im Bereich der Konstruktion und Wartung von Fotovoltaikanlagen entstand SETYS-SOLAR zum Waschen der Solarzellen. Einsetzbar auf Maschinen der Serie JOY-1-SOLAR und JOY-2-SOLAR, ohne Änderungen an der Hydraulik oder an der Tragkonstruktion. Die Ausrüstung besteht aus einer Drehbürste mit Durchmesser 1000 mm für eine Nutzlänge von 3200/6600 mm und wird mit patentierten wasserabweisenden Spezialwerkstoffen ausgeführt, welche die Reinigung der Solarzellen ohne die Verursachung von Kratzern zulassen. Die Bürste wird durch einen mit der Maschinenanlage verbundenen Hydraulik- Getriebemotor betätigt. Das System zur Positionierung der Bürste auf den Solarzellen wird hydraulisch so gesteuert, dass es stets in der korrekten Arbeitsposition bleibt. SETYS-SOLAR kann nach entsprechender technischer Prüfung auf Raupen-Baggern oder Baustellenmaschinen montiert werden. Tecnische Eigenschaften Wassereinspritzsammler komplett mit Düsen und Ventilen zur Gewährleistung des Waschens in beiden Laufrichtungen. Membranpumpe mit maximalem Fördervolumen von 150 Litern/Minute bei 50 bar, geeignet auch für Waschwasser mit Beifügung von Additiven. Sammeltank mit 1000 Liter Fassungsvermögen, montiert auf seitlicher Halterung, leicht zugänglich und auswechselbar.

HYDRA SL-200-1250

HYDRA SL200-1250 - Bohrlafette zur Montage am Bagger HYDRA SL-200-1250

HYDRA SL-200-1250

Mittlere Bohrlafette für Trägermaschinen und Fahrzeuge von 1,5 - 10 Tonnen Geeignet für beispielsweise Minibagger, Autokrane oder Anhänger Lieferumfang:Komplett mit Schalttafel zur Steuerung der Kopfschwenkrichtung sowie der Auf- und Abfahrt der GondelEin Hydraulik-Getriebemotor im oberen Teil der Lafette erlaubt die Auf- und Abfahrt des Schwenkkopfes Lieferbare Lafetten Hublängen: 1250 mm 1750 mm 2250 mm 3250 mm Optional: Verfügbare Drehköpfe: TR-150, 1570 Nm TR-350, 3430 Nm TR-600, 5880 Nm Montierbare Erdbohrer: T-3 T-4 T-5 T-1000 Mechanischer Drehsattel Mechanische Spannbacke für Bohrgestänge: MD-135 für D=30 - 135 mm MD-205 D= 40 - 205 mm Zweifach drehbarer hydraulische Drehsattel, 360° vertikal und horizontal drehbar Winde Stützfüße für horizontale Bohrungen Funk-Fernbedienung

HYDRA T-1

HYDRA T1 - Erdbohrer zur Montage an Mini-Bagger, max. Bohr-Ø 350 mm HYDRA T-1

HYDRA T-1

6-kant-Aufnahme: 50 mmDrehmoment: 980 NmMax. Bohr-Ø 350 mm -> Bohr-tiefe 1 mMin. Bohr-Ø 50 mm -> Bohr-tiefe 7 mHydraulik: Max. 30 L/min bei 250 barDie Kopfstücke sind mit Halterungsvorrichtung, doppeltem Gelenk für die Montage am Arm des Baggers und Sechskantwelle für den Anschluss des Bohrers ausgerüstetDie Spiralbohrer können schnell mittels Sechskantanschluss verlängert werden, durch die Kardanwelle kann die Montage horizontal erfolgenWir liefern auch Sonderausführungen die auf Führungen sowohl für horizontale als auch vertikale Bohrungen geeignet sindBei der Anfrage bitte stets angeben:Für welches Gelände: weiches oder felsiges (bestimmt den Aufbau und die wechselbaren Zähne)Rechts- oder Linkslauf AusführungGewünschter Bohr-Ø

HYDRA T-1000-O

HYDRA T1000 - Erdbohrer zur Montage an Bagger von 15 bis 30Tonnen HYDRA T-1000-O

HYDRA T-1000-O

6-kant-Aufnahme: 70 mm Drehmoment: 9800 Nm Hydraulik: Max. 130 L/min bei 260 bar mit OrbitalmotorDie Kopfstücke sind mit Halterungsvorrichtung, doppeltem Gelenk für die Montage am Arm des Baggers und Sechskantwelle für den Anschluss des Bohrers ausgerüstet Die Spiralbohrer können schnell mittels Sechskantanschluss verlängert werden, durch die Kardanwelle kann die Montage horizontal erfolgen Wir liefern auch Sonderausführungen die auf Führungen sowohl für horizontale als auch vertikale Bohrungen geeignet sind Bei der Anfrage bitte stets angeben:Für welches Gelände: weiches oder felsiges (bestimmt den Aufbau und die wechselbaren Zähne) Rechts- oder Linkslauf Ausführung Gewünschter Bohr-ØAuf Anfrage kann der Erdbohrer auch mit Kolbenmotor angeboten werden.

HYDRA T-12000

HYDRA T12000 - Erdbohrer zur Montage an Bagger ab 30 Tonnen HYDRA T-12000

HYDRA T-12000

4-kant-Aufnahme: 130 mm Drehmoment: 156.000 Nm Hydraulik: Max. 350 L/min bei 400 bar Die Kopfstücke sind mit Halterungsvorrichtung, doppeltem Gelenk für die Montage am Arm des Baggers und Vierkantwelle für den Anschluss des Bohrers ausgerüstet Die Spiralbohrer können schnell mittels Vierkantanschluss verlängert werden, durch die Kardanwelle kann die Montage horizontal erfolgen Wir liefern auch Sonderausführungen die auf Führungen sowohl für horizontale als auch vertikale Bohrungen geeignet sind Bei der Anfrage bitte stets angeben: Für welches Gelände: weiches oder felsiges (bestimmt den Aufbau und die wechselbaren Zähne) Rechts- oder Linkslauf Ausführung Gewünschter Bohr-Ø

HYDRA T-16000

HYDRA T16000 - Erdbohrer zur Montage an Bagger ab 30 Tonnen HYDRA T-16000

HYDRA T-16000

4-kant-Aufnahme: 150 mm Drehmoment: 156.000 Nm Hydraulik: Max. 500 L/min bei 430 bar Die Kopfstücke sind mit Halterungsvorrichtung, doppeltem Gelenk für die Montage am Arm des Baggers und Vierkantwelle für den Anschluss des Bohrers ausgerüstet Die Spiralbohrer können schnell mittels Vierkantanschluss verlängert werden, durch die Kardanwelle kann die Montage horizontal erfolgen Wir liefern auch Sonderausführungen die auf Führungen sowohl für horizontale als auch vertikale Bohrungen geeignet sind Bei der Anfrage bitte stets angeben: Für welches Gelände: weiches oder felsiges (bestimmt den Aufbau und die wechselbaren Zähne) Rechts- oder Linkslauf Ausführung Gewünschter Bohr-Ø

HYDRA T-2

HYDRA T2 - Erdbohrer zur Montage an Mini-Bagger, max. Bohr-Ø 450 mm HYDRA T-2

HYDRA T-2

6-kant-Aufnahme: 50 mm Drehmoment: 1960 Nm Max. Bohr-Ø 450 mm -> Bohr-tiefe 1 m Min. Bohr-Ø 50 mm -> Bohr-tiefe 10 m Hydraulik: Max. 50 L/min bei 250 bar Die Kopfstücke sind mit Halterungsvorrichtung, doppeltem Gelenk für die Montage am Arm des Baggers und Sechskantwelle für den Anschluss des Bohrers ausgerüstet Die Spiralbohrer können schnell mittels Sechskantanschluss verlängert werden, durch die Kardanwelle kann die Montage horizontal erfolgen Wir liefern auch Sonderausführungen die auf Führungen sowohl für horizontale als auch vertikale Bohrungen geeignet sind Bei der Anfrage bitte stets angeben:Für welches Gelände: weiches oder felsiges (bestimmt den Aufbau und die wechselbaren Zähne) Rechts- oder Linkslauf Ausführung Gewünschter Bohr-Ø

HYDRA T-2000-O

HYDRA T2000 - Erdbohrer zur Montage an Bagger von 15 bis 30 Tonnen HYDRA T-2000-O

HYDRA T-2000-O

6-kant-Aufnahme: 70 mm Drehmoment: 19.600 Nm Hydraulik: Max. 150 L/min bei 260 bar mit OrbitalmotorDie Kopfstücke sind mit Halterungsvorrichtung, doppeltem Gelenk für die Montage am Arm des Baggers und Sechskantwelle für den Anschluss des Bohrers ausgerüstet Die Spiralbohrer können schnell mittels Sechskantanschluss verlängert werden, durch die Kardanwelle kann die Montage horizontal erfolgen Wir liefern auch Sonderausführungen die auf Führungen sowohl für horizontale als auch vertikale Bohrungen geeignet sind Bei der Anfrage bitte stets angeben: Für welches Gelände: weiches oder felsiges (bestimmt den Aufbau und die wechselbaren Zähne) Rechts- oder Linkslauf Ausführung Gewünschter Bohr-ØAuf Anfrage kann der Erdbohrer auch mit Kolbenmotor angeboten werden.

HYDRA T-24000

HYDRA T24000 - Erdbohrer zur Montage an Bagger ab 30 Tonnen HYDRA T-24000

HYDRA T-24000

6-kant-Aufnahme: 177 mm Drehmoment: 235.000 Nm Hydraulik: Max. 500 L/min bei 430 bar Die Kopfstücke sind mit Halterungsvorrichtung, doppeltem Gelenk für die Montage am Arm des Baggers und Sechskantwelle für den Anschluss des Bohrers ausgerüstet Die Spiralbohrer können schnell mittels Sechskantanschluss verlängert werden, durch die Kardanwelle kann die Montage horizontal erfolgen Wir liefern auch Sonderausführungen die auf Führungen sowohl für horizontale als auch vertikale Bohrungen geeignet sind Bei der Anfrage bitte stets angeben: Für welches Gelände: weiches oder felsiges (bestimmt den Aufbau und die wechselbaren Zähne) Rechts- oder Linkslauf Ausführung Gewünschter Bohr-Ø

HYDRA T-3

HYDRA T3 - Erdbohrer zur Montage an Mini-Bagger, max. Bohr-Ø 550 mm HYDRA T-3

HYDRA T-3

6-kant-Aufnahme: 50 mm Drehmoment: 2900 Nm Max. Bohr-Ø 550 mm -> Bohr-tiefe 1 m Min. Bohr-Ø 100 mm -> Bohr-tiefe 11 m Hydraulik: Max. 75 L/min bei 250 bar Die Kopfstücke sind mit Halterungsvorrichtung, doppeltem Gelenk für die Montage am Arm des Baggers und Sechskantwelle für den Anschluss des Bohrers ausgerüstet Die Spiralbohrer können schnell mittels Sechskantanschluss verlängert werden, durch die Kardanwelle kann die Montage horizontal erfolgen Wir liefern auch Sonderausführungen die auf Führungen sowohl für horizontale als auch vertikale Bohrungen geeignet sind Bei der Anfrage bitte stets angeben:Für welches Gelände: weiches oder felsiges (bestimmt den Aufbau und die wechselbaren Zähne) Rechts- oder Linkslauf Ausführung Gewünschter Bohr-Ø

HYDRA T-3000-O

HYDRA T3000 - Erdbohrer zur Montage an Bagger von 15 bis 30 Tonnen HYDRA T-3000-O

HYDRA T-3000-O

6-kant-Aufnahme: 70 mm Drehmoment: 29.400 Nm Hydraulik: Max. 160 L/min bei 260 bar mit OrbitalmotorDie Kopfstücke sind mit Halterungsvorrichtung, doppeltem Gelenk für die Montage am Arm des Baggers und Sechskantwelle für den Anschluss des Bohrers ausgerüstet Die Spiralbohrer können schnell mittels Sechskantanschluss verlängert werden, durch die Kardanwelle kann die Montage horizontal erfolgen Wir liefern auch Sonderausführungen die auf Führungen sowohl für horizontale als auch vertikale Bohrungen geeignet sind Bei der Anfrage bitte stets angeben: Für welches Gelände: weiches oder felsiges (bestimmt den Aufbau und die wechselbaren Zähne) Rechts- oder Linkslauf Ausführung Gewünschter Bohr-ØAuf Anfrage kann der Erdbohrer auch mit Kolbenmotor angeboten werden.

HYDRA T-4

HYDRA T4 - Erdbohrer zur Montage an Mini-Bagger, max. Bohr-Ø 600 mm HYDRA T-4

HYDRA T-4

6-kant-Aufnahme: 70 mm Drehmoment: 3900 Nm Max. Bohr-Ø 600 mm -> Bohr-tiefe 1.0 m Min. Bohr-Ø 100 mm -> Bohr-tiefe 15.0 m Hydraulik: Max. 100 L/min bei 250 bar Die Kopfstücke sind mit Halterungsvorrichtung, doppeltem Gelenk für die Montage am Arm des Baggers und Sechskantwelle für den Anschluss des Bohrers ausgerüstet Die Spiralbohrer können schnell mittels Sechskantanschluss verlängert werden, durch die Kardanwelle kann die Montage horizontal erfolgen Wir liefern auch Sonderausführungen die auf Führungen sowohl für horizontale als auch vertikale Bohrungen geeignet sind Bei der Anfrage bitte stets angeben:Für welches Gelände: weiches oder felsiges (bestimmt den Aufbau und die wechselbaren Zähne) Rechts- oder Linkslauf Ausführung Gewünschter Bohr-Ø

HYDRA T-4000-O

HYDRA T4000 - Erdbohrer zur Montage an Bagger von 15 bis 30 Tonnen HYDRA T-4000-O

HYDRA T-4000-O

6-kant-Aufnahme: 70 mm Drehmoment: 39.200 Nm Hydraulik: Max. 240 L/min bei 370 bar mit OrbitalmotorDie Kopfstücke sind mit Halterungsvorrichtung, doppeltem Gelenk für die Montage am Arm des Baggers und Sechskantwelle für den Anschluss des Bohrers ausgerüstet Die Spiralbohrer können schnell mittels Sechskantanschluss verlängert werden, durch die Kardanwelle kann die Montage horizontal erfolgen Wir liefern auch Sonderausführungen die auf Führungen sowohl für horizontale als auch vertikale Bohrungen geeignet sind Bei der Anfrage bitte stets angeben: Für welches Gelände: weiches oder felsiges (bestimmt den Aufbau und die wechselbaren Zähne) Rechts- oder Linkslauf Ausführung Gewünschter Bohr-ØAuf Anfrage kann der Erdbohrer auch mit Kolbenmotor angeboten werden.

HYDRA T-5

HYDRA T5 - Erdbohrer zur Montage an Mini-Bagger, max. Bohr-Ø 700 mm HYDRA T-5

HYDRA T-5

6-kant-Aufnahme: 70 mm Drehmoment: 980 Nm Max. Bohr-Ø 700 mm -> Bohr-tiefe 1 m Min. Bohr-Ø 100 mm -> Bohr-tiefe 20 m Hydraulik: Max. 120 L/min bei 250 bar Die Kopfstücke sind mit Halterungsvorrichtung, doppeltem Gelenk für die Montage am Arm des Baggers und Sechskantwelle für den Anschluss des Bohrers ausgerüstet Die Spiralbohrer können schnell mittels Sechskantanschluss verlängert werden, durch die Kardanwelle kann die Montage horizontal erfolgen Wir liefern auch Sonderausführungen die auf Führungen sowohl für horizontale als auch vertikale Bohrungen geeignet sind Bei der Anfrage bitte stets angeben:Für welches Gelände: weiches oder felsiges (bestimmt den Aufbau und die wechselbaren Zähne) Rechts- oder Linkslauf Ausführung Gewünschter Bohr-Ø

HYDRA T-5000

HYDRA T5000, Erdbohrer zur Montage an Bagger von 15 bis 30 Tonnen HYDRA T-5000

HYDRA T-5000

6-kant-Aufnahme: 70 mm Drehmoment: 49.000 Nm Hydraulik: Max. 280 L/min bei 370 bar Die Kopfstücke sind mit Halterungsvorrichtung, doppeltem Gelenk für die Montage am Arm des Baggers und Sechskantwelle für den Anschluss des Bohrers ausgerüstet Die Spiralbohrer können schnell mittels Sechskantanschluss verlängert werden, durch die Kardanwelle kann die Montage horizontal erfolgen Wir liefern auch Sonderausführungen die auf Führungen sowohl für horizontale als auch vertikale Bohrungen geeignet sind Bei der Anfrage bitte stets angeben: Für welches Gelände: weiches oder felsiges (bestimmt den Aufbau und die wechselbaren Zähne) Rechts- oder Linkslauf Ausführung Gewünschter Bohr-Ø

HYDRA T-8000

HYDRA T8000 - Erdbohrer zur Montage an Bagger von 15 bis 30 Tonnen HYDRA T-8000

HYDRA T-8000

6-kant-Aufnahme: 100 mm Drehmoment: 78.450 Nm Hydraulik: Max. 350 L/min bei 370 bar Die Kopfstücke sind mit Halterungsvorrichtung, doppeltem Gelenk für die Montage am Arm des Baggers und Sechskantwelle für den Anschluss des Bohrers ausgerüstet Die Spiralbohrer können schnell mittels Sechskantanschluss verlängert werden, durch die Kardanwelle kann die Montage horizontal erfolgen Wir liefern auch Sonderausführungen die auf Führungen sowohl für horizontale als auch vertikale Bohrungen geeignet sind Bei der Anfrage bitte stets angeben: Für welches Gelände: weiches oder felsiges (bestimmt den Aufbau und die wechselbaren Zähne) Rechts- oder Linkslauf Ausführung Gewünschter Bohr-Ø

HYDRA JOY-1-GEO

JOY-1-GEO - self-propelled drill HYDRA JOY-1-GEO

HYDRA JOY-1-GEO

These units are built with small dimensions but for high operating performance and are particularly suitable for use in confined spaces and for all types of soil. The machine can be equipped with radio control. Hydraulic drilling machine JOY-1-GEO Light series drilling machine for making vertical or inclined holes. Different types of operating heads can be mounted on the machine to carry out different drilling techniques: With Auger By rotopercussion hammersDrilling with air Down-the-hole hammer drilling All drilling machines can be equipped with a removable hydraulic center, so that safe work is possible in closed or dangerous spaces. The use of these drilling units is particularly suitable for all companies, as they are compact and easy to transport even with medium-sized vehicles. The machine is particularly suitable for the following work, both indoors and outdoors: Foundation excavations Minipiles Tie rods Test drilling small fountain / wells Equipped with: Tracked chassis with hydraulic motors and negative safety brake Support frame complete with hydraulic supports with articulated plates and shut-off valves for machine positioning, hydraulic cylinders with articulated connections for inclination of the derrick Hydraulic unit with quiet diesel engine approx. 29 KW, exhaust class STAGE V, triple pump, electrovalves, oil tank complete with filter, filler cap, drain, sight level Fuel tank with filler cap, drain and level 6 lever valves to control the working position of the machine 8 lever valves to control the drill head and the clamp Height adjustment for raising / lowering the mast, stroke 500mm Electrical system with command center, safety switch, rotating beacon and headlights for the work areaTechnical specifications Substructure Length: 1420 mm Width: 1000 mm Sliding jaws: 230 mm Rolls: 3 + 3 Stabilizers: 4-3 Engine Output: approx. 35 hp Sound insulation: 80 dB Drilling slide Length depending on: 1250/1750/2250/35050 mm Thrust: 2000 kg Train: 2000 kg Vertical carriage right left / right: 15 ° / 15 ° hydraulic or 90 ° / 90 ° hydraulic and mechanical Counter slide: +500 mm Double clamping jaws with unscrewing device: MD135 Øi 250 mm / MD205 Øi 200 Rotation Minimum / maximum torque: variable / variable 3432 - 5883 Nm Weight With minimum equipment: 1450 kg Optional accessories: Carriage SL-200, hub 1250 mm Tried the carriage by 500 mm Tried the carriage by 1000 mm Tried the carriage by 2000 mm Double clamp with screw-on function Ø 135 mm Double clamp with screw-on function Ø 205 mm TR-22 drill head with hollow shaft and hammer THOR-18Rotation: 60 l / min. at 180 bar, 280 rpm, 980 Nm Impact: 25 l / min. at 180 bar, 1600 min-1 TR-150 drill head with hollow shaft and hammer THOR-62 Rotation: 80 l / min. at 180 bar, 320 min-1, 1570 Nm Impact: 30 l / min. at 180 bar, 1600 min-1 TR-350 drill head with hollow shaft, swivel joint Rotation: 90 l / min. at 180 bar, 280 min & supmin; ¹, 3432 Nm TR-600 drill head with hollow shaft, swivel joint Rotation: 90 l / min at 180 bar, 240 min-1, 5883 Nm TR-600-V high-speed drill head for stony ground Water / air connection head 2 "low pressure (20 bar) remote control Screw pump 150 l / min. at 30 bar 900 kg winch with 25 meters of rope Turntable for carriage 90 ° right / 90 ° left Turntable for carriage 15 ° right / 15 ° leftThis description is for guidance only. You cannot order this product online. The order process only triggers a request.

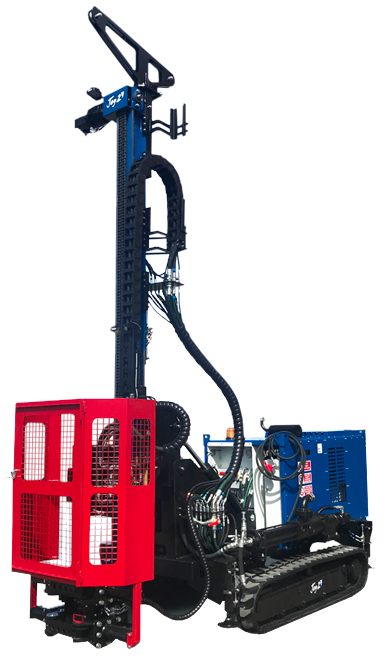

HH-JOY-4-G

JOY-2-GEO - self-propelled drill HH-JOY-4-G

HH-JOY-4-G

These units are built with small dimensions but for high operating performance and are particularly suitable for use in confined spaces and for all types of soil. The machine can be equipped with radio control. Hydraulic drilling machine JOY-1-GEO Light series drilling machine for making vertical or inclined holes. Different types of operating heads can be mounted on the machine to carry out different drilling techniques: With Auger By rotopercussion hammersDrilling with air Down-the-hole hammer drilling All drilling machines can be equipped with a removable hydraulic center, so that safe work is possible in closed or dangerous spaces. The use of these drilling units is particularly suitable for all companies, as they are compact and easy to transport even with medium-sized vehicles. The machine is particularly suitable for the following work, both indoors and outdoors: Foundation excavations Minipiles Tie rods Test drilling small fountain / wells Equipped with: Tracked chassis with hydraulic motors and negative safety brake Support frame complete with hydraulic supports with articulated plates and shut-off valves for machine positioning, hydraulic cylinders with articulated connections for inclination of the derrick Hydraulic unit with quiet diesel engine approx. 29 KW, exhaust class STAGE V, triple pump, electrovalves, oil tank complete with filter, filler cap, drain, sight level Fuel tank with filler cap, drain and level 6 lever valves to control the working position of the machine 8 lever valves to control the drill head and the clamp Height adjustment for raising / lowering the mast, stroke 500mm Electrical system with command center, safety switch, rotating beacon and headlights for the work areaTechnical specifications Substructure Length: 1420 mm Width: 1000 mm Sliding jaws: 230 mm Rolls: 3 + 3 Stabilizers: 4-3 Engine Output: approx. 35 hp Sound insulation: 80 dB Drilling slide Length depending on: 1250/1750/2250/35050 mm Thrust: 2000 kg Train: 2000 kg Vertical carriage right left / right: 15 ° / 15 ° hydraulic or 90 ° / 90 ° hydraulic and mechanical Counter slide: +500 mm Double clamping jaws with unscrewing device: MD135 Øi 250 mm / MD205 Øi 200 Rotation Minimum / maximum torque: variable / variable 3432 - 5883 Nm Weight With minimum equipment: 1450 kg Optional accessories: Carriage SL-200, hub 1250 mm Tried the carriage by 500 mm Tried the carriage by 1000 mm Tried the carriage by 2000 mm Double clamp with screw-on function Ø 135 mm Double clamp with screw-on function Ø 205 mm TR-22 drill head with hollow shaft and hammer THOR-18Rotation: 60 l / min. at 180 bar, 280 rpm, 980 Nm Impact: 25 l / min. at 180 bar, 1600 min-1 TR-150 drill head with hollow shaft and hammer THOR-62 Rotation: 80 l / min. at 180 bar, 320 min-1, 1570 Nm Impact: 30 l / min. at 180 bar, 1600 min-1 TR-350 drill head with hollow shaft, swivel joint Rotation: 90 l / min. at 180 bar, 280 min & supmin; ¹, 3432 Nm TR-600 drill head with hollow shaft, swivel joint Rotation: 90 l / min at 180 bar, 240 min-1, 5883 Nm TR-600-V high-speed drill head for stony ground Water / air connection head 2 "low pressure (20 bar) remote control Screw pump 150 l / min. at 30 bar 900 kg winch with 25 meters of rope Turntable for carriage 90 ° right / 90 ° left Turntable for carriage 15 ° right / 15 ° leftThis description is for guidance only. You cannot order this product online. The order process only triggers a request.

HYDRA JOY-2-GEO

JOY-2-GEO - self-propelled drill HYDRA JOY-2-GEO

HYDRA JOY-2-GEO

These units are built with small dimensions but for high operating performance and are particularly suitable for use in confined spaces and for all types of soil. The machine can be equipped with radio control. Hydraulic drilling machine JOY-1-GEO Light series drilling machine for making vertical or inclined holes. Different types of operating heads can be mounted on the machine to carry out different drilling techniques: With Auger By rotopercussion hammersDrilling with air Down-the-hole hammer drilling All drilling machines can be equipped with a removable hydraulic center, so that safe work is possible in closed or dangerous spaces. The use of these drilling units is particularly suitable for all companies, as they are compact and easy to transport even with medium-sized vehicles. The machine is particularly suitable for the following work, both indoors and outdoors: Foundation excavations Minipiles Tie rods Test drilling small fountain / wells Equipped with: Tracked chassis with hydraulic motors and negative safety brake Support frame complete with hydraulic supports with articulated plates and shut-off valves for machine positioning, hydraulic cylinders with articulated connections for inclination of the derrick Hydraulic unit with quiet diesel engine approx. 29 KW, exhaust class STAGE V, triple pump, electrovalves, oil tank complete with filter, filler cap, drain, sight level Fuel tank with filler cap, drain and level 6 lever valves to control the working position of the machine 8 lever valves to control the drill head and the clamp Height adjustment for raising / lowering the mast, stroke 500mm Electrical system with command center, safety switch, rotating beacon and headlights for the work areaTechnical specifications Substructure Length: 1420 mm Width: 1000 mm Sliding jaws: 230 mm Rolls: 3 + 3 Stabilizers: 4-3 Engine Output: approx. 35 hp Sound insulation: 80 dB Drilling slide Length depending on: 1250/1750/2250/35050 mm Thrust: 2000 kg Train: 2000 kg Vertical carriage right left / right: 15 ° / 15 ° hydraulic or 90 ° / 90 ° hydraulic and mechanical Counter slide: +500 mm Double clamping jaws with unscrewing device: MD135 Øi 250 mm / MD205 Øi 200 Rotation Minimum / maximum torque: variable / variable 3432 - 5883 Nm Weight With minimum equipment: 1450 kg Optional accessories: Carriage SL-200, hub 1250 mm Tried the carriage by 500 mm Tried the carriage by 1000 mm Tried the carriage by 2000 mm Double clamp with screw-on function Ø 135 mm Double clamp with screw-on function Ø 205 mm TR-22 drill head with hollow shaft and hammer THOR-18Rotation: 60 l / min. at 180 bar, 280 rpm, 980 Nm Impact: 25 l / min. at 180 bar, 1600 min-1 TR-150 drill head with hollow shaft and hammer THOR-62 Rotation: 80 l / min. at 180 bar, 320 min-1, 1570 Nm Impact: 30 l / min. at 180 bar, 1600 min-1 TR-350 drill head with hollow shaft, swivel joint Rotation: 90 l / min. at 180 bar, 280 min & supmin; ¹, 3432 Nm TR-600 drill head with hollow shaft, swivel joint Rotation: 90 l / min at 180 bar, 240 min-1, 5883 Nm TR-600-V high-speed drill head for stony ground Water / air connection head 2 "low pressure (20 bar) remote control Screw pump 150 l / min. at 30 bar 900 kg winch with 25 meters of rope Turntable for carriage 90 ° right / 90 ° left Turntable for carriage 15 ° right / 15 ° leftThis description is for guidance only. You cannot order this product online. The order process only triggers a request.

Earth drills, drill rigs, drill rigs and pile drivers

Our extensive product range includes earth drills, drill heads, self-propelled drilling rigs and drill rigs from renowned manufacturers known for their quality, reliability and performance. Explore the world of drilling and pile driving and find the perfect tools for your projects.

Attachment Earth Drilling Rigs

Our add-on earth drilling rigs are the ideal choice for performing efficient and precise drilling work. With a wide range of attachments for hydraulic excavators, you can perfectly adapt the equipment to your needs.

Attachable drill heads

Our attachable drill heads are characterized by their robustness and durability. Damped shafts are also available for some models.

Self-propelled drilling rigs

Our self-propelled drill rigs are the perfect solution for projects where drilling in the vertical, inclined and horizontal directions is critical. Whether rotary drilling, percussive drilling, drilling with air or down-the-hole hammer drilling, our self-propelled drilling rigs cover the widest range of applications.

Drill mounts

HYDRA's drill mounts are universally applicable, as they can be manufactured in four different strong columns in various lengths. They provide a solid basis for efficient drilling and pile driving and can be adapted to a wide variety of requirements.