DYNASET

Hydraulic equipment from Dynaset converts the hydraulic power of mobile machines, vehicles or ships and uses it to generate electricity, high pressure water, compressed air, magnetic energy, vibratory movements or pressure amplification.

The world's best ratio of power to size (power-to-size) enables easy installation on mobile machines. Dynaset products are made by skilled workers in Finland.

KW HYDRAULIK GMBH guarantees advice, sales and service in Germany.

Filter

–

Hydraulik: 44-69 L/min (max. intern begrenzt) bei max. 350 bar Generatorleistung: 10 kW Max Magnetspulenleistung: 1,0- 9,1 kW Entmagnetisierung: 0,8 s Magnetspulenwiderstand (20C°): 5,4-100 Ohm Betriebsspannung: 220 VDC Hilfsstrom: OptionalNEU! Die neue CMG Generation von Dynaset ist mit einem Druckspeicher ausgestattet, der 50 bar Rückstaudruck in der Tankleitung anstelle der 5 bar bei den Vorgängermodellen ermöglicht. Deshalb wird keine Leckageleitung benötigt.

Hydraulik: 68-102 L/min (max. intern begrenzt) bei max. 260 bar Generatorleistung: 15 kW Max Magnetspulenleistung: 14,5 kW Entmagnetisierung: 0,8 s Magnetspulenwiderstand (20C°): 3,6 - 50 Ohm Betriebsspannung: 220 VDC Hilfsstrom: OptionalNEU! Die neue CMG Generation von Dynaset ist mit einem Druckspeicher ausgestattet, der 50 bar Rückstaudruck in der Tankleitung anstelle der 5 bar bei den Vorgängermodellen ermöglicht. Deshalb wird keine Leckageleitung benötigt.

Hydraulik: 94 L/min (max. intern begrenzt) bei 210 bar Generatorleistung: 20 kW Max Magnetspulenleistung: 19,5 kW Entmagnetisierung: 0,8s Magnetspulenwiderstand (20C°): 2,6 - 50 Ohm Betriebsspannung: 220 VDC Hilfsstrom: OptionalNEU! Die neue CMG Generation von Dynaset ist mit einem Druckspeicher ausgestattet, der 50 bar Rückstaudruck in der Tankleitung anstelle der 5 bar bei den Vorgängermodellen ermöglicht. Deshalb wird keine Leckageleitung benötigt.

Hydraulik: 122 L/min (max. intern begrenzt) bei 210 bar Generatorleistung: 30 kW Max Magnetspulenleistung: 29,5 kW Entmagnetisierung: 0,8s Magnetspulenwiderstand (20C°): 1,8-100 Ohm Betriebsspannung: 220 VDC Hilfsstrom: OptionalNEU! Die neue CMG Generation von Dynaset ist mit einem Druckspeicher ausgestattet, der 50 bar Rückstaudruck in der Tankleitung anstelle der 5 bar bei den Vorgängermodellen ermöglicht. Deshalb wird keine Leckageleitung benötigt.

Hydraulik: 21-31 L/min (max. intern begrenzt) bei max. 350 bar Generatorleistung: 3 kW Max Magnetspulenleistung: 0,5 - 3 kW Entmagnetisierung: 0,8 sMagnetspulenwiderstand (20C°): 15-100 Ohm Betriebsspannung: 220 VDC Hilfsstrom: OptionalNEU! Die neue CMG Generation von Dynaset ist mit einem Druckspeicher ausgestattet, der 50 bar Rückstaudruck in der Tankleitung anstelle der 5 bar bei den Vorgängermodellen ermöglicht. Deshalb wird keine Leckageleitung benötigt.

Hydraulik: 167 L/min (max. intern begrenzt) bei 210 bar Generatorleistung: 40 kW Max Magnetspulenleistung: 39,5 kW Entmagnetisierung: 0,8s Magnetspulenwiderstand (20C°): 1,3 - 100 Ohm Betriebsspannung: 220 VDC Hilfsstrom: OptionalNEU! Die neue CMG Generation von Dynaset ist mit einem Druckspeicher ausgestattet, der 50 bar Rückstaudruck in der Tankleitung anstelle der 5 bar bei den Vorgängermodellen ermöglicht. Deshalb wird keine Leckageleitung benötigt.

Hydraulik: 3248 L/min (max. intern begrenzt) bei max. 350 bar Generatorleistung: 6 kW Max Magnetspulenleistung: 0,5 -5,5 kW Entmagnetisierung: 0,8 s Magnetspulenwiderstand (20C°): 8,8-100 Ohm Betriebsspannung: 220 VDC Hilfsstrom: OptionalNEU! Die neue CMG Generation von Dynaset ist mit einem Druckspeicher ausgestattet, der 50 bar Rückstaudruck in der Tankleitung anstelle der 5 bar bei den Vorgängermodellen ermöglicht. Deshalb wird keine Leckageleitung benötigt.

Hydraulic power packs with 18 hp B & S petrol engine with recoil starter and electric starter Delivery rate: 38 L / min. at 140 bar, 25 L / min. at max. 250 bar Control valve on the pump Incl. 28 liter oil tank, fuel tank, oil cooling (air oil), oil filter Sturdy protective frame with wheels and handles facilitate transport This pump can be used up to an operating pressure of 250 bar Connection for two devices, FlatFace couplings (P + T)

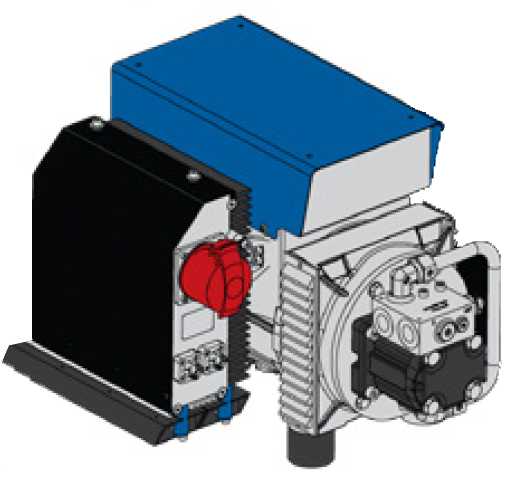

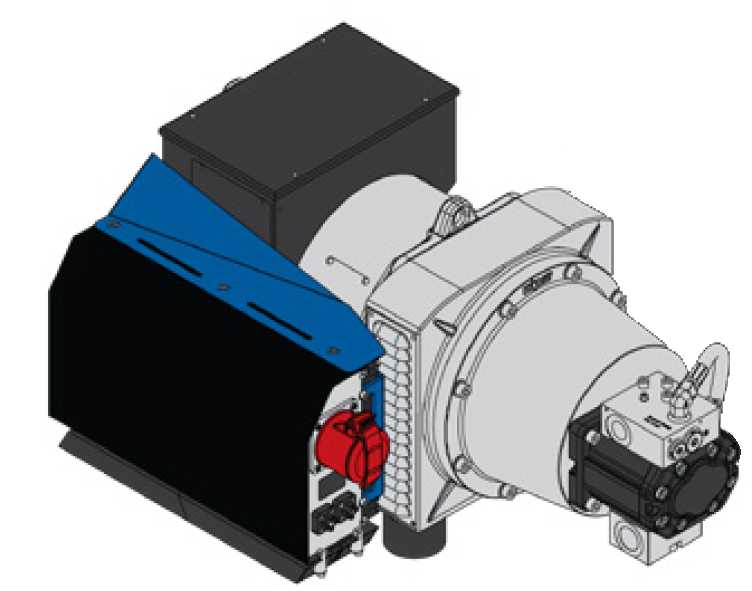

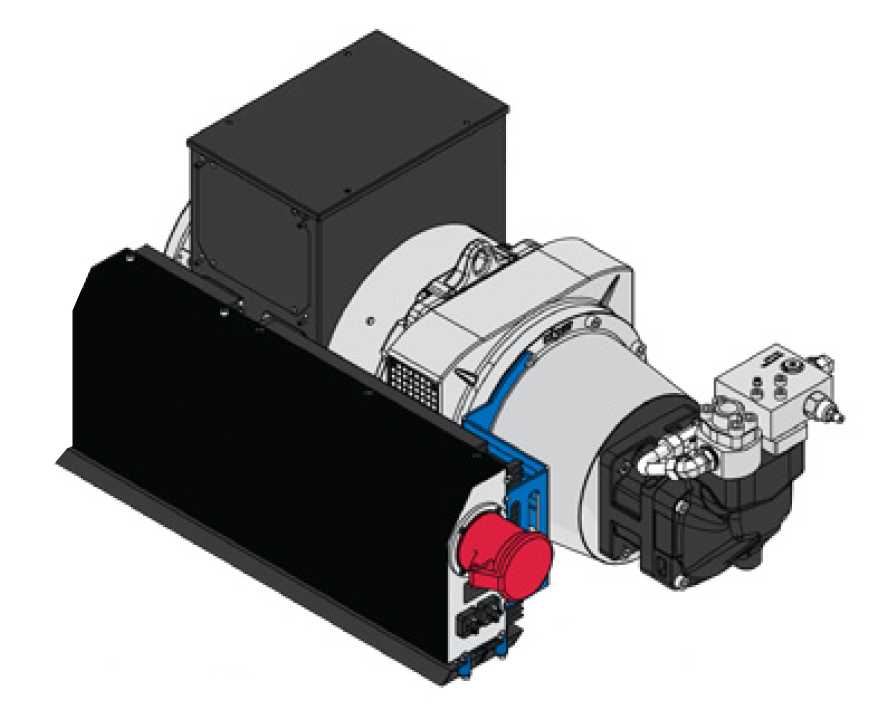

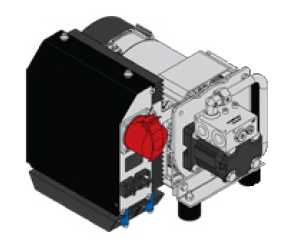

Anwendungsbereiche: Bodenwäsche, Spülbohren, Gestängeschmierung, Bohrlochstabilisierung, Druckbeaufschlagung, usw… Eigenschaften: Arbeiten mit allen Bohrflüssigkeiten: Bentonit, und Mischpolymerisate, Schäummittel, usw… Ausgangsleistung der Bohrspülung: 70 L/min bei 160 bar Druckverhältnis 1 : 1,12 Leistung: 19 kW Hydraulikleistung: 90 L/min bei max. 210 bar

Anwendungsbereiche: Bodenwäsche, Spülbohren, Gestängeschmierung, Bohrlochstabilisierung, Druckbeaufschlagung, usw… Eigenschaften: Arbeiten mit allen Bohrflüssigkeiten: Bentonit, und Mischpolymerisate, Schäummittel, usw… Ausgangsleistung der Bohrspülung: 40 L/min bei 200 bar Druckverhältnis 1 : 1,26 Leistung: 13 kW Hydraulikleistung: 55 L/min bei max. 210 bar

Anwendungsbereiche: Bodenwäsche, Spülbohren, Gestängeschmierung, Bohrlochstabilisierung, Druckbeaufschlagung, usw… Eigenschaften: Arbeiten mit allen Bohrflüssigkeiten: Bentonit, und Mischpolymerisate, Schäummittel, usw… Ausgangsleistung der Bohrspülung: 23 L/min bei 210 bar Druckverhältnis 1 : 1,18 Leistung: 8,0 kW Hydraulikleistung: 35 L/min bei max. 220 bar

Anwendungsbereiche: Bodenwäsche, Spülbohren, Gestängeschmierung, Bohrlochstabilisierung, Druckbeaufschlagung, usw… Eigenschaften: Arbeiten mit allen Bohrflüssigkeiten: Bentonit, und Mischpolymerisate, Schäummittel, usw… Ausgangsleistung der Bohrspülung: 250 L/min bei 250 bar Druckverhältnis 1 : 1,06Leistung: 85 kW Hydraulikleistung: 280 L/min bei max. 210 bar

Anwendungsbereiche: Bodenwäsche, Spülbohren, Gestängeschmierung, Bohrlochstabilisierung, Druckbeaufschlagung, usw… Eigenschaften: Arbeiten mit allen Bohrflüssigkeiten: Bentonit, und Mischpolymerisate, Schäummittel, usw…Ausgangsleistung der Bohrspülung: 40 L/min bei 40 barDruckverhältnis 1 : 0,2Leistung: 2,6 kWHydraulikleistung: 8 L/min bei max. 210 bar

Anwendungsbereiche: Bodenwäsche, Spülbohren, Gestängeschmierung, Bohrlochstabilisierung, Druckbeaufschlagung, usw… Eigenschaften: Arbeiten mit allen Bohrflüssigkeiten: Bentonit, und Mischpolymerisate, Schäummittel, usw… Ausgangsleistung der Bohrspülung: 150 L/min bei 90 bar Druckverhältnis 1 : 0,52 Leistung: 23 kW Hydraulikleistung: 85 L/min bei max. 210 bar

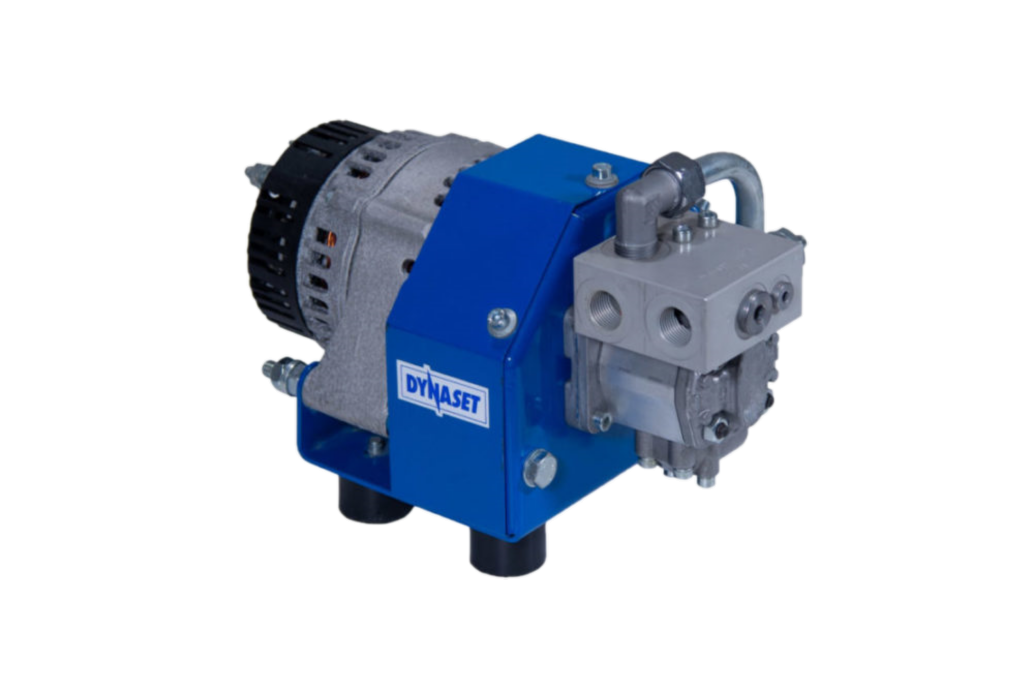

zum Anschluss an ein HydrauliksystemHydraulik: 14-34 L/min. bei max. 210 bar Hydraulikmotor mit Überstromventil und BypassGenerator: 14 Volt Gleichstrom 70 ASchutzklasse IP23

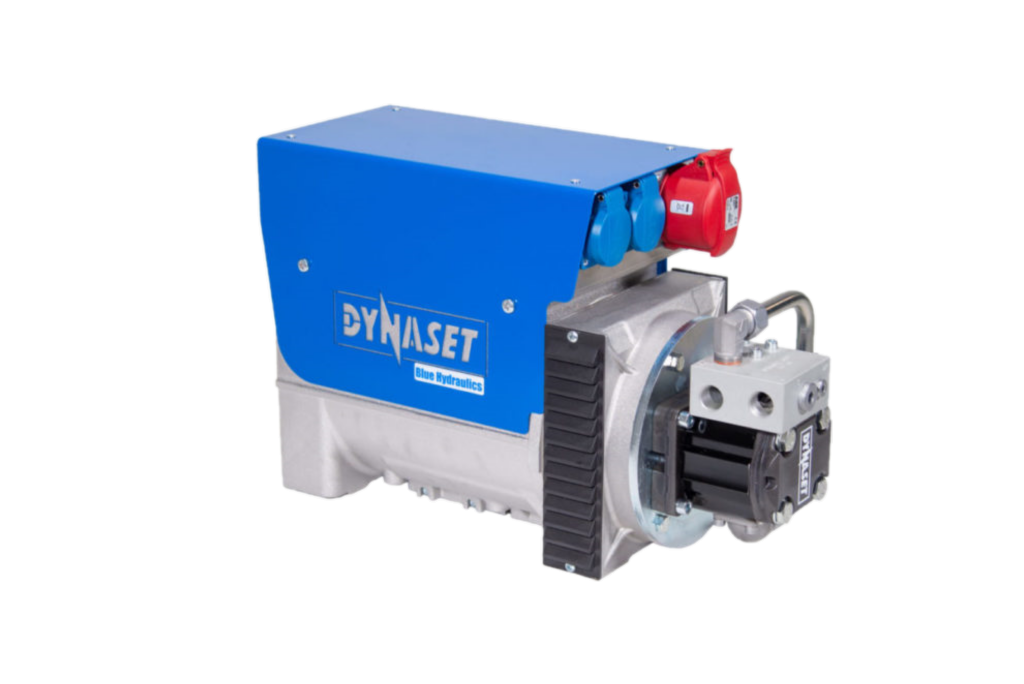

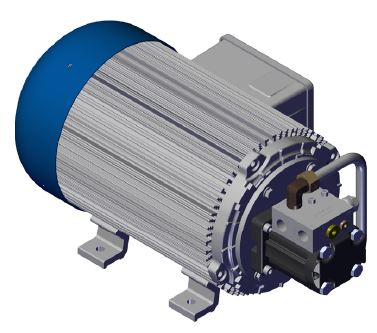

zum Anschluss an ein HydrauliksystemHydraulik: 52-78 L/min bei max. 210 bar Hydraulikmotor mit Überstromventil und Bypass. Generator:- Leistung 10 kVA- 230 Volt / 21,7 A / 2 Steckdosen - 400 Volt / 14,4 A / 1 Steckdose Spannungsregelung: AVRFrequenzkontrolle: FLCSchutzklasse IP23

zum Anschluss an ein HydrauliksystemHydraulik: 52-73 L/min bei max. 210 bar Hydraulikmotor mit Überstromventil und BypassGenerator: - Leistung 10,1 kVA-230 Volt / 21,7 A / 2 Steckdosen -400 Volt / 14,6 A / 1 Steckdose Spannungsregelung: AVRFrequenzkontrolle: FLCSchutzklasse IP54Auf Anfrage mit Kabelausgang ohne Steckdosen erhältlich.

zum Anschluss an ein HydrauliksystemHydraulik: 56-84 L/min bei max. 210 bar Hydraulikmotor mit Überstromventil und BypassGenerator:- Leistung 12 kVA- 230 Volt / 26,1 A / 2 Steckdosen - 400 Volt / 17,3 A / 1 Steckdose Spannungsregelung: AVRFrequenzkontrolle: FLCSchutzklasse IP23

zum Anschluss an ein HydrauliksystemHydraulik: 58-81 L/min bei max. 210 bar Hydraulikmotor mit Überstromventil und BypassGenerator: - Leistung 12,1 kVA-230 Volt / 26,1 A / 2 Steckdosen -400 Volt / 17,5 A / 1 Steckdose Spannungsregelung: AVRFrequenzkontrolle: FLCSchutzklasse IP54 Auf Anfrage mit Kabelausgang ohne Steckdosen erhältlich.

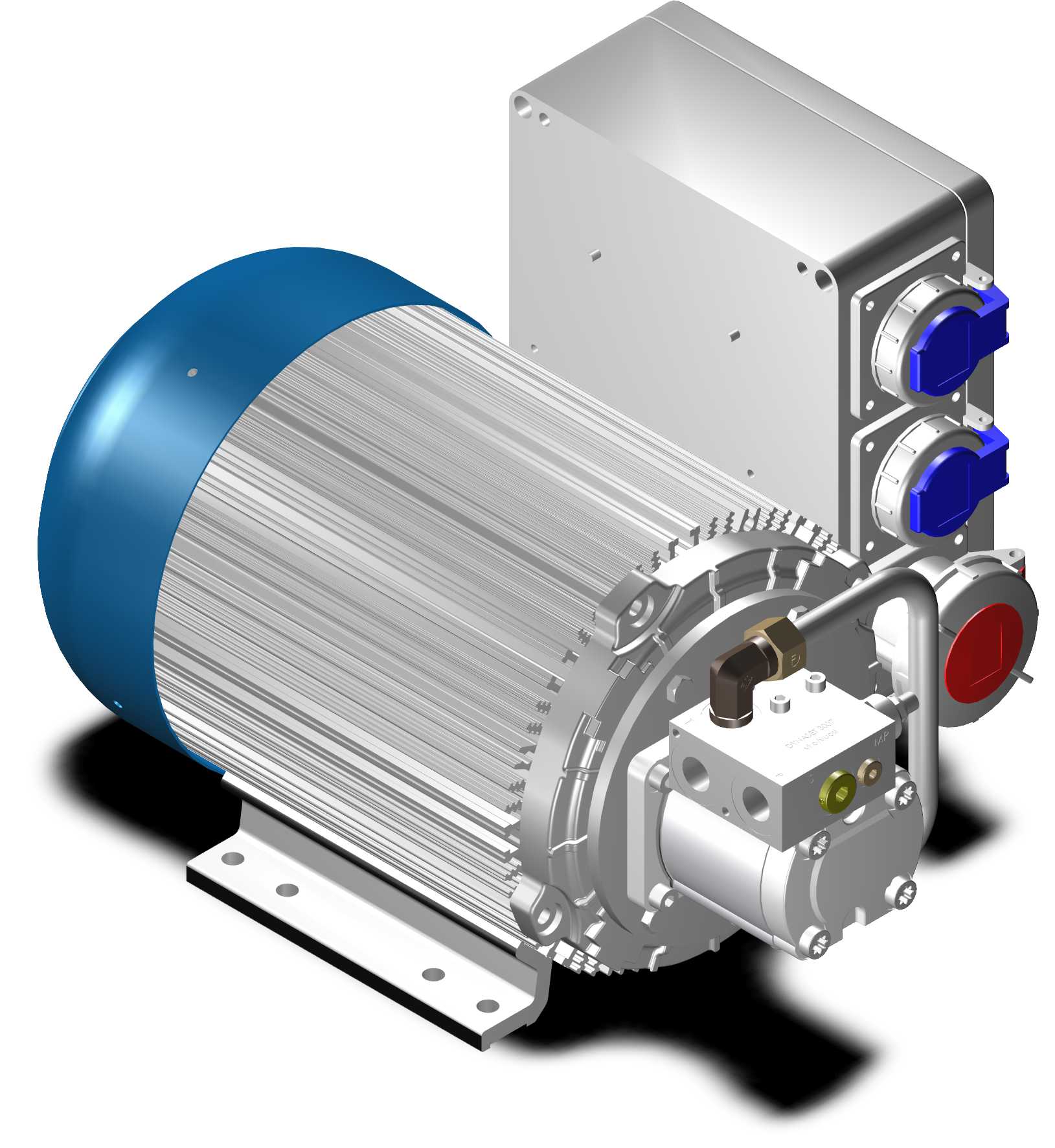

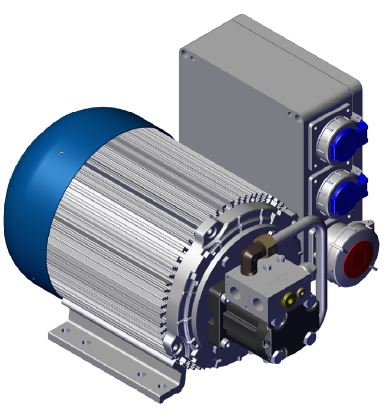

zum Anschluss an ein HydrauliksystemHydraulik: 65-85 L/min bei max. 210 bar Hydraulikmotor mit Überstromventil und BypassGenerator: - Leistung 15,1 kVA-230 Volt / 32,6 A / 2 Steckdosen -400 Volt / 21,8 A / 1 Steckdose Spannungsregelung: AVR Frequenzkontrolle: FLC2 Schutzklasse IP54 Auf Anfrage mit Kabelausgang ohne Steckdosen erhältlich.

zum Anschluss an ein HydrauliksystemHydraulik: 66-99 L/min bei max. 260 bar Hydraulikmotor mit Überstromventil und BypassGenerator:- Leistung 19 kVA- 230 Volt / 41,4 A / 1 Steckdosen - 400 Volt / 27,4 A / 2 Steckdose Spannungsregelung: AVRFrequenzkontrolle: FLCSchutzklasse IP23

zum Anschluss an ein HydrauliksystemHydraulik: 83-113 L/min bei max. 280 bar Hydraulikmotor mit Überstromventil und Bypass. Generator:- Leistung 19 kVA- 230 Volt / 41,4 A / 1 Steckdosen - 400 Volt / 27,4 A / 2 Steckdose Spannungsregelung: AVRFrequenzkontrolle: FLCSchutzklasse IP23

zum Anschluss an ein Hydrauliksystem Hydraulik: 26-44 L/min bei max. 210 bar Hydraulikmotor mit Überstromventil und Bypass Generator: 28 Volt Gleichstrom 70 ASchutzklasse IP23

zum Anschluss an ein Hydrauliksystem Hydraulik: 82-97 L/min bei max. 210 bar Hydraulikmotor mit Überstromventil und BypassGenerator:- Leistung 20,1 kVA- 230 Volt / 43,7 A / 2 Steckdosen - 400 Volt / 29,0 A / 1 Steckdose Spannungsregelung: AVRFrequenzkontrolle: FLCSchutzklasse IP54Auf Anfrage mit Kabelausgang ohne Steckdosen erhältlich.