ERKO

ERKO ist heute ein moderner familiengeführter Entwickler und Hersteller von Werkzeugen und Maschinen für die Stromschienenbearbeitung. Die polnische Firma, deren Wurzel auf ein Schmiede- und Schlosserwerksatt aus dem Jahre 1938 zurückgeht, hat sich bis heute kontinuierlich weiterentwickelt zu einem modernen europäischen Komplettanbieter für Werkzeuge und Maschinen. In Deutschland hat die KW Hydraulik GmbH den Service und Vertrieb der Werkzeuge und des Zubehörs rund um die Stromschienenbearbeitung sowie weiterer Ausrüstung für den Schaltschrank- und Schaltanlagenbau übernommen.

Filter

–

%

equipped with 2.5 m hydraulic hose with quick-release coupling with foot switch compatible with press heads, cutting heads and other devices with quick-release coupling Voltage: 230V AC / 50 Hz Motor power: 0.75 kW Delivery rate: 0.66 L/min. Operating temperature: -25°C to +40°C Dimensions: 336x235x406 mm Weight: 25 kg

%

Bending, cutting, punching and offset of solid and laminated copper and aluminum rails. Compact construction for use in workshops and on the construction site. Easy and quick change of tool inserts.Bending insert inside radius 8 mm, for material up to a width of 120 mm incl. angle sensor for repeatable shutdown when producing several identical parts Cutting insert for solid rails up to 12x120 mm Cutting insert for laminated rails up to 10x100 mm Punching for solid and laminated rails up to a material thickness of 12 mm. 5 round hole inserts: 9 mm (M8) / 11 mm (M10) / 13 mm (M12) / 17 mm (M16) / 21 mm (M20) 4 oval hole inserts: 9x21 mm / 11x21 mm / 13x21 mm / 17 x 21 mm Offset tool for producing a step with material thickness - used for example for extending a rail. Delivery:- SSBZ basic unit incl. angle sensor - SSBZ-BW bending insert- SSBZ-SW-M cutting insert for solid rails- SSBZ-SW-L cutting insert for laminated rails - SSBZ-LW-2 punching insert incl. 5 round hole and 4 oval hole inserts - SSBZ-KW offset tool- NP-7 Electrohydraulic pump 230 Volt, 700 bar, incl. angle switch-off function and foot switch - 3 meters hydraulic hose - Tool case

%

Bending, cutting, punching and offset of solid and laminated copper and aluminum rails. Compact construction for use in workshops and on the construction site. Easy and quick change of tool inserts.Bending insert inside radius 8 mm, for material up to a width of 120 mm incl. angle sensor for repeatable shutdown when producing several identical parts Cutting insert for solid rails up to 12x120 mm Cutting insert for laminated rails up to 10x100 mm Punching for solid and laminated rails up to a material thickness of 12 mm. 5 round hole inserts: 9 mm (M8) / 11 mm (M10) / 13 mm (M12) / 17 mm (M16) / 21 mm (M20) 4 oval hole inserts: 9x21 mm / 11x21 mm / 13x21 mm / 17 x 21 mm Offset tool for producing a step with material thickness - used for example for extending a rail. Delivery:- SSBZ basic unit incl. angle sensor - SSBZ-BW bending insert- SSBZ-SW-M cutting insert for solid rails- SSBZ-SW-L cutting insert for laminated rails - SSBZ-LW-2 punching insert incl. 5 round hole and 4 oval hole inserts - SSBZ-KW offset tool- NP-7 Electrohydraulic pump 230 Volt, 700 bar, incl. angle switch-off function and foot switch - 3 meters hydraulic hose - Tool case

%

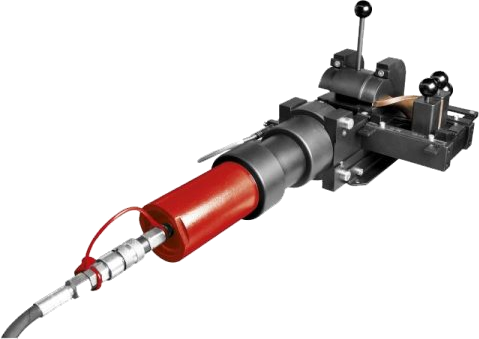

Bending device for bending Al and Cu conductor rails in transverse position: rail width 20 ÷ 50 mm rail thickness 5 ÷ 10 mm bending angle up to 90° Features: equipped with bending insert one set of rollers (two support rollers and one punch including clamping device) for conductor rails of 5 and 10 mm thickness rollers for Al conductor rails on request electric bending angle sensor (HGD 105 limit switch) guarantees the repeatability of the angle only with drive unit (to be ordered separately). For connection to hydraulic foot pump H 800 and hydraulic drive units AH 100, AH 500, AH 550 and AH 500L.Dimensions (LxWxH): 790x250x230 mmWeight: 49 kgCompressive force: 190 kNOperating pressure: 630 bar

%

Bending, cutting, punching and offset of solid and laminated copper and aluminum rails. Compact construction for use in workshops and on the construction site. Easy and quick change of tool inserts.Bending insert inside radius 8 mm, for material up to a width of 120 mm incl. angle sensor for repeatable shutdown when producing several identical parts Cutting insert for solid rails up to 12x120 mm Cutting insert for laminated rails up to 10x100 mm Punching for solid and laminated rails up to a material thickness of 12 mm. 5 round hole inserts: 9 mm (M8) / 11 mm (M10) / 13 mm (M12) / 17 mm (M16) / 21 mm (M20) 4 oval hole inserts: 9x21 mm / 11x21 mm / 13x21 mm / 17 x 21 mm Offset tool for producing a step with material thickness - used for example for extending a rail. Delivery:- SSBZ basic unit incl. angle sensor - SSBZ-BW bending insert- SSBZ-SW-M cutting insert for solid rails- SSBZ-SW-L cutting insert for laminated rails - SSBZ-LW-2 punching insert incl. 5 round hole and 4 oval hole inserts - SSBZ-KW offset tool- NP-7 Electrohydraulic pump 230 Volt, 700 bar, incl. angle switch-off function and foot switch - 3 meters hydraulic hose - Tool case

%

Bending, cutting, punching and offset of solid and laminated copper and aluminum rails. Compact construction for use in workshops and on the construction site. Easy and quick change of tool inserts.Bending insert inside radius 8 mm, for material up to a width of 120 mm incl. angle sensor for repeatable shutdown when producing several identical parts Cutting insert for solid rails up to 12x120 mm Cutting insert for laminated rails up to 10x100 mm Punching for solid and laminated rails up to a material thickness of 12 mm. 5 round hole inserts: 9 mm (M8) / 11 mm (M10) / 13 mm (M12) / 17 mm (M16) / 21 mm (M20) 4 oval hole inserts: 9x21 mm / 11x21 mm / 13x21 mm / 17 x 21 mm Offset tool for producing a step with material thickness - used for example for extending a rail. Delivery:- SSBZ basic unit incl. angle sensor - SSBZ-BW bending insert- SSBZ-SW-M cutting insert for solid rails- SSBZ-SW-L cutting insert for laminated rails - SSBZ-LW-2 punching insert incl. 5 round hole and 4 oval hole inserts - SSBZ-KW offset tool- NP-7 Electrohydraulic pump 230 Volt, 700 bar, incl. angle switch-off function and foot switch - 3 meters hydraulic hose - Tool case

%

The processing trolley for cutting, punching, U and Z bending of Al and Cu busbars and for pressing in nuts:Rail width 30 ÷ 125 mmRail thickness 5 ÷ 12 mmBending angle up to 90°Characteristics: easily adjustable bending angle sensorBuilt-in ruler (line scale)Height adjustment of the punch press housing (accuracy up to 1 mm)Burr-free round and oval perforations burr-free cuttingCompatible with ERKO hydraulic heads (hydraulic line with quick-release coupling PM 630 bar)A standard set for pressing in nuts is the insert SH 407 and the round hole punch SH 403 (to be ordered separately), see table below Overall dimensions (LxWxH): 1280x850x1420 mm; Weight with standard accessories: 280 kg; Operating pressure: 630 bar; Power supply: 3 x 230V/400V; 1.1kV

%

Bending and cutting device for precise bending and cutting of Al and Cu busbars: Width of the cut bar 50÷ 180 mm Width of the bent bar 50÷ 200 mm Thickness of the bent and cut bar 5 ÷ 15 mm Bending angle up to 90° Features: Fully automatic compensation of material deflection Standard radii of bending punches: R5; R8; R10; R12; R15; R20 (other radii on request in consultation with our technical department) It is possible to use up to 4 bending inserts (3 standard inserts: 1 is included in the price, others must be ordered separately) simple operator panel makes the programming time of the device much shorter ergonomically shaped work plate enables precise bending of long rails stable construction with low weight powerful, compact hydraulic unit with low power consumption makes the device very economical the device can be adapted to the customer's individual requirements on request Overall dimensions (LxWxH): 1200x1230x1274 mm Weight with standard accessories: 450 kgCompressive force 30 kN at 400 bar. Power supply: 3 x 400V/230V; 1.68 kW optional: - HG-201 - bending inserts - HG-205 - cutting insert

%

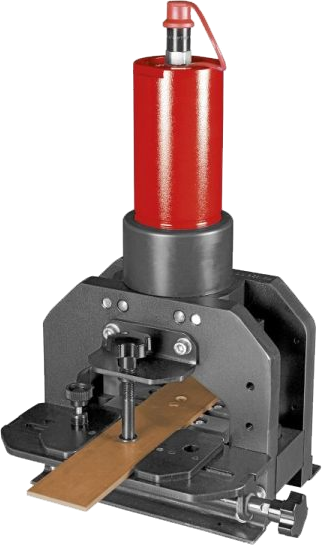

Cutting device for hydraulic operation, for cutting Al and Cu busbars: Busbar width 30 ÷ 125 mm Rail thickness 5 ÷ 12 mm burr-free and waste-free cutting to length For connection to hydraulic foot pump H 800 and hydraulic drive units AH 100, AH 500, AH 550 and AH 500L.Dimensions (LxWxH): 310x240x475 mm Weight: 32 kg Compressive force: 190 kN Operating pressure: 630 bar

%

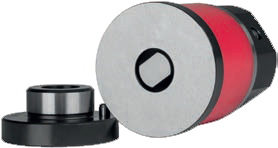

enables the mounting of punch inserts in the HGD125 tool Punch inserts, round, HGD-103 available diameters: 6.6 / 8.5 / 11 / 13 / 17 / 21 mm Punch inserts, oval, HGD-104 available dimensions: 8.5x12 / 11x16 / 13x18 / 17x21 mm

%

Punch inserts for tool HGD125 Punch inserts, round, HGD-103 available diameters: 6.6 / 8.5 / 11 / 13 / 17 / 21 mm

%

Punch inserts for tool HGD125 Punch inserts, oval, HGD-104 available diameters: 8.5x12 / 11x16 / 13x18 / 17x21 mm

%

enables the bending of solid rails rail width 30 ÷ 125 mm rail thickness 5 ÷ 10 mm Bending angle up to 90 °

%

enables solid rails to be bent. With angle indicator. In combination with sensor HGD105 (order separately) the device switches off when the set angle is reached. Rail width 30 ÷ 125 mm Rail thickness 5 ÷ 10 mm Bending angle up to 90 °

%

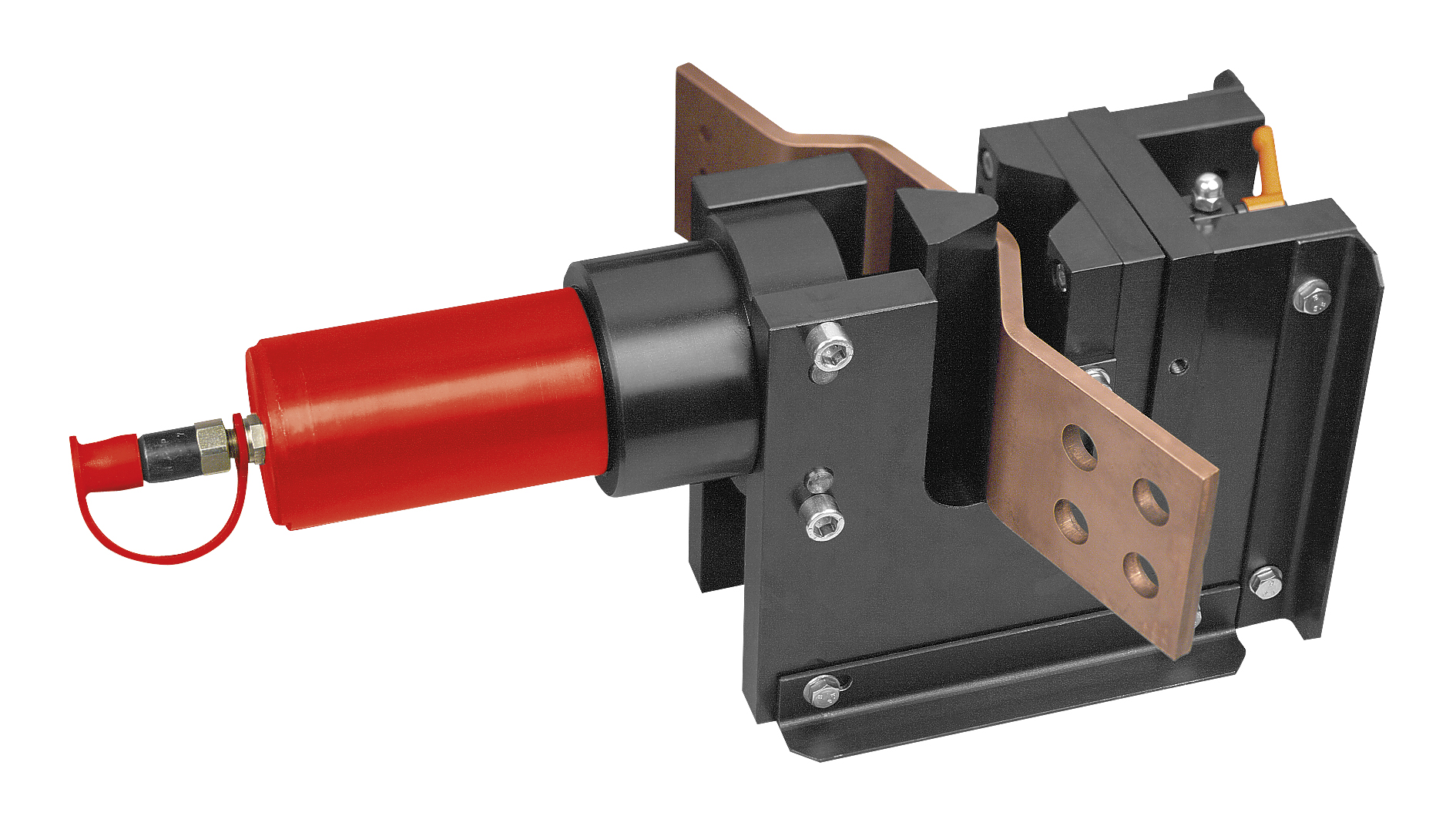

Bending and punching device for hydraulic operation, for bending and punching Al and Cu conductor rails: Rail width 30 ÷ 125 mm Rail thickness 5 ÷ 10 mm Bending angle up to 90 ° Round holes 6.6 ÷ 21 mm Oval holes 8.5 ÷ 21 mm Equipped as standard with length stop for positioning the conductor rails electric bending angle sensor (HGD 105 limit switch) guarantees the repeatability of the angle only with ERKO drive unit series AH (to be ordered separately) For connection to hydraulic foot pump H 800 and hydraulic drive units AH 100, AH 500, AH 550 and AH 500L. Dimensions (LxWxH): 370x260x585 mm Weight: 42 kgPressure force: 190 kN Operating pressure: 630 bar

%

Bending and punching device for hydraulic operation, for bending and punching Al and Cu conductor rails: Rail width 30 ÷ 125 mm Rail thickness 5 ÷ 10 mm Bending angle up to 90 ° Round holes 6.6 ÷ 21 mm Oval holes 8.5 ÷ 21 mm Equipped as standard with length stop for positioning the conductor rails electric bending angle sensor (HGD 105 limit switch) guarantees repeatability of the angle only with ERKO drive unit AH series (to be ordered separately) with hydraulic drive unit AH500L-230V Scope of delivery: - ERKO-HGD-125 - Bending and punching device - ERKO-HGD-121-S - Bending insert (punch and die) - ERKO-HGD-105 - Bending sensor - ERKO-HGD-102 - Punching insert holder - ERKO-HGD-103 - Hole inserts, round: Ø 6.6 / 8.5 / 11 / 13 / 17 / 21 mm - ERKO-HGD-104 - Punch inserts, oval: 8.5x12 / 11x16 / 13x18 / 17x21 mm - Tool case for punch inserts- ERKO-AH-500-L - Hydraulic unit (230 volt) with foot switch and hydraulic hose

%

Processing device for punching, cutting and pre-stripping laminated busbars: Busbar width 30 ÷ 100 mm Busbar thickness 4 ÷ 10 mm Punching of round holes 6.6 ÷ 21 mm Simple insertion of hole punches Easy change of inserts for cutting and stripping Length stop and centering mask for precise cutting to length ATTENTION: Limit switch and insert for cutting HSE105- to be ordered separately For connection to hydraulic foot pump H 800 and hydraulic drive units AH 100, AH 500, AH 550 and AH 500L. Dimensions (LxWxH): 490x390x490 mmWeight: 32.5 kgCompressive force: 190 kN Operating pressure: 630 bar

%

Processing device for punching, cutting and pre-stripping laminated busbars and for stripping the insulation:Busbar width 30 ÷ 100 mm Busbar thickness 4 ÷ 10 mm Punching round holes 6.6 ÷ 21 mm Simple insertion of hole punches easy change of inserts for cutting and stripping Length stop and centering mask for precise cutting to length ATTENTION: Limit switch and insert for cutting HSE105- to be ordered separately For connection to hydraulic foot pump or hydraulic drive units AH 100, AH 500, AH 550 and AH 500L. Operating pressure: 630 bar Scope of delivery: - ERKO-HSE100 - Cutting & punching tool for laminated rails - ERKO-HSE105 - Stripping insert for laminated rails - ERKO-HSE103 - Punching inserts, round: Ø 6.6 / 8.5 / 11 / 13 / 17 / 21 mm - Case for storing the punching inserts

%

Hole inserts for laminated rails available diameters: 6.6 / 8.5 / 11 / 13 / 17 / 21 mm

%

cuts into the insulation of laminated rails without damaging these copper rails. Makes work easier and saves time compared to manual work with a stripping knife.

%

Bending device for axial bending of Al and Cu busbars: Busbar width 20 ÷ 50 mm Busbar thickness 3 ÷ 10 mm Bending angle up to 90° Features: electric bending angle sensor (limit switch) guarantees the repeatability of the angle for rail thickness up to 5 mm with a spacer sleeve in the swivel bracket Equipped with a support for regulating the rail width For connection to hydraulic drive units AH 100, AH 500, AH 550 and AH 500L. Dimensions (LxWxH): 720x300x190 mmWeight: 42 kgOperating pressure: 630 bar

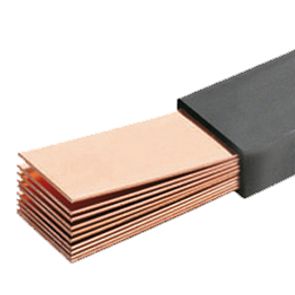

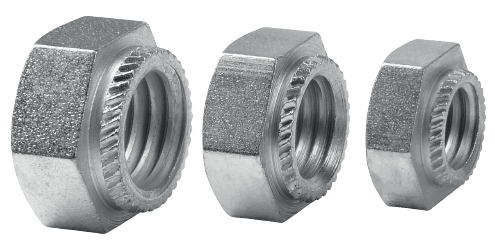

Press-in nuts for busbars Packaging unit: 50 pieces Available sizes: M8 / M10 / M12

%

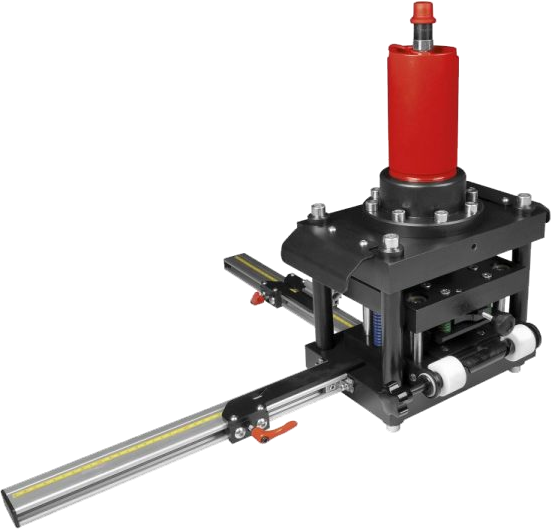

The mobile processing station for cutting, U and Z bending, punching holes in Al and Cu busbars and for pressing in nuts: Rail width 30 ÷ 125 mm Rail thickness 5 ÷ 12 mm Bending angle 15 ÷ 90° Features: equipped with an adjustable bending angle indicator (scale with a resolution of 5°, measurement does not include the elasticity of the rail) built-in length stop with tape measure (setting range ruler 200 mm, accuracy up to 1 mm) regulation of the height of the universal working cylinder (accuracy up to 1 mm) Burr-free round and oval perforation Burr-free cutting Standard set for pressing in nuts SH 307, SH 303 For connection to hydraulic drive units AH 100, AH 500, AH 550 and AH 500L or foot pump H 800 (to be ordered separately). Dimensions (LxWxH): 550x540x430 mm Weight with standard accessories: 57 kg Pressure force: 190 kN Operating pressure: 630 bar Supplied without hydraulic unit and without tool inserts