Air compressors / Vacuum / Fans

Discover our high-quality compressors, blowers/fans and vacuum pumps for your projects. Inquire now!

- Products

- Hydraulic Pumps

- Cable crimping tools

- Cutting tools

- Busbar machining center

- PTO for small vehicles

- Punching tools

- Steel and bolt cutter

- Generators / Magnets / Welding

- Air compressors / Vacuum / Fans

- Water high pressure pumps

- Submersible pumps

- Self-propelled machines

- Drills / impact wrench / auger

- XLPE cable preparing

- Bending and straightening tools

- Demolition Shears

- Concrete crushers / pulverizers

- Breakers

- Pile driver / Vibratory plates / Vibration

- Angle Grinder / Grinder

- Pipe processing

- Diamond saws

- Chainsaws / pruning shears / log splitters / grabs

- Torque wrench

- Demolition and sorting grabs

- Pile cutter, pipe cutter, felling grapple

- Excavator buckets

- Cable winch

- Stroke cylinders

- Multi-Tools

- Remote controlled machines / robots

- Tools for meter mounting

- Solar Installation Tools

- Underwater Tools

- Tools for Railway Maintenance

- Fiber Optic Processing

DO-AV-28-H

AV28 - hydraulically driven blower, 2,000 m³ / h DO-AV-28-H

DO-AV-28-H

Capacity: 2,000 m³/h Air outlet: D = 200 mm Drive: 20-40 L /min at 140 bar Dimensions: 70x60x50 cm Weight: 25 kg

HK-1000/12-35-F-U

HK1000 - Hydraulically driven pneumatic piston compressor 1,000 L/min. at max. 12 bar (174 PSI) HK-1000/12-35-F-U

HK-1000/12-35-F-U

Flow rate eff .: 1,000 L/min. at max. 12 BAR (174 PSI) Oil flow (input): 35 L/min. at max. 230 BAR (Flow: 12 up to max. 50 L/min.)Integrated accumulator: 14 litersThe engine is connected directly to the crankshaft of the piston unit for robust power transfer and maximum efficiency. The movement of the piston directs compressed air to the frame tank, from where it can be removed directly for pneumatic applications. It is a compact, easy to install compressor unit for the mobile supply of compressed air devices. The HK compressor is ideal for mobile use on drills, tractors and excavators.Options There are various additional options available for this compressor, allowing it to be used in all conditions and in all work environments. It is also available with an additional hose reel, which makes the unit even more flexible for mobile use. The compressed air hose is protected from damage by rolling up and can be stored to save space.

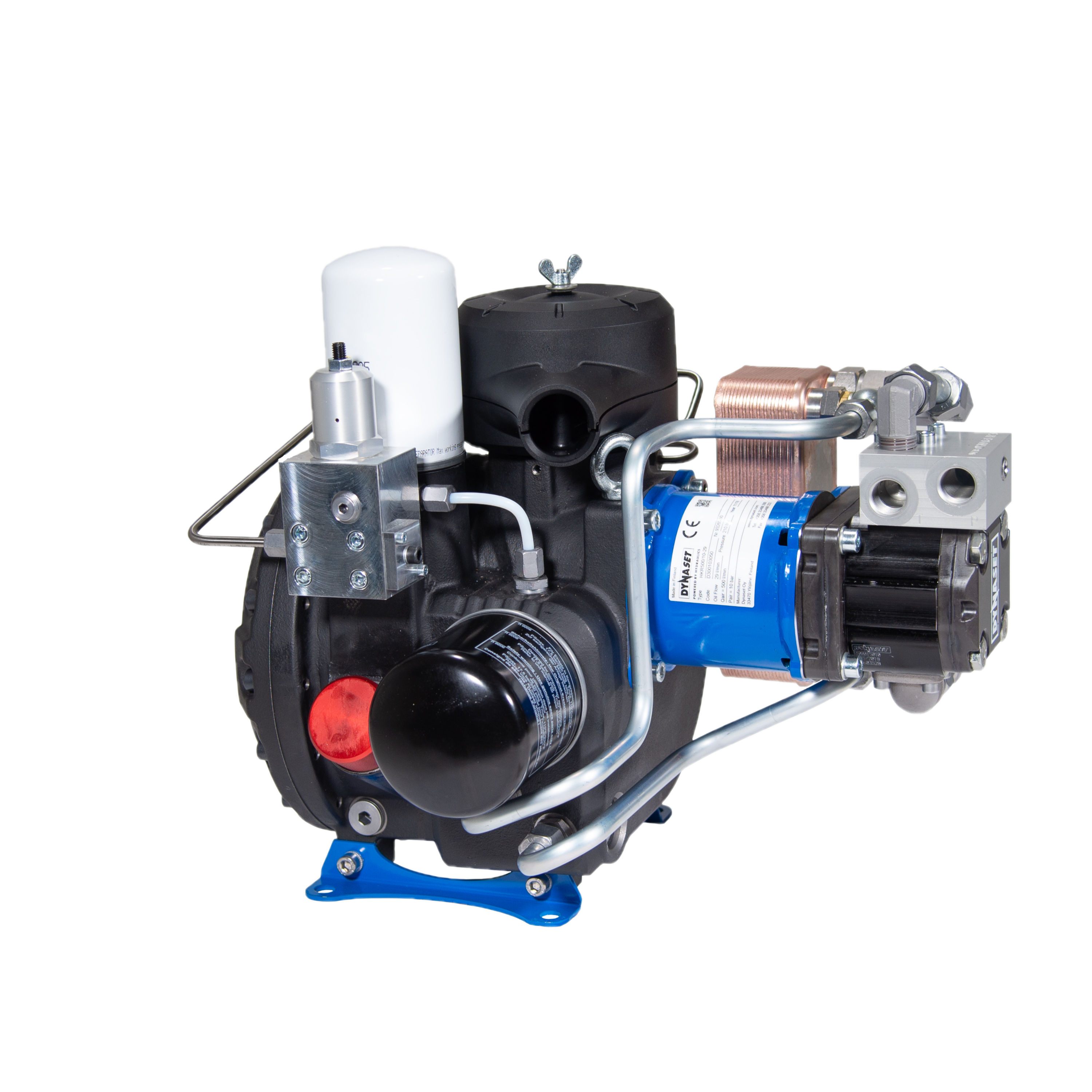

HK-450/8-15-F-U

HK450 - Hydraulically driven pneumatic piston compressor 450 L/min. at max. 8 bar (116 PSI) HK-450/8-15-F-U

HK-450/8-15-F-U

Flow rate eff .: 450 L/min. at max. 8 BAR (116 PSI) (Special version with max. 10 BAR available)Oil flow (input): 15 L/min. at max. 210 BAR (Range: 10 up to max. 35 L/min.)Integrated accumulator: 4 litersThe engine is connected directly to the crankshaft of the piston unit for robust power transfer and maximum efficiency. The movement of the piston directs compressed air to the frame tank, from where it can be removed directly for pneumatic applications. Thanks to these integrated tanks, no additional space is needed for compressed air storage. It is a compact, easy to install compressor unit for the mobile supply of compressed air devices. The HK compressor is ideal for mobile use on drills, tractors and excavators.Options There are various additional options available for this compressor, allowing it to be used in all conditions and in all work environments. It is also available with an additional hose reel, which makes the unit even more flexible for mobile use. The compressed air hose is protected from damage by rolling up and can be stored to save space.

HKR11000/10-184

HKR11000 - Hydraulically driven pneumatic screw compressor 11,000 L/min. at max. 10 bar (145 PSI) HKR11000/10-184

HKR11000/10-184

Effective delivery rate: 11,000 L/min at 6 bar (87 PSI), max. 10 bar (145 PSI) Oil quantity: 165-275 L/min at max. 380 barAutomatic speed control Air pressure control with pressure relief Pressure gauge

HKR11000/10-270

HKR11000 - Hydraulically driven pneumatic screw compressor 11,000 L/min. at max. 10 bar (145 PSI) HKR11000/10-270

HKR11000/10-270

Effective delivery rate: 11,000 L/min at 6 bar (87 PSI), max. 10 bar (145 PSI) Oil quantity: 165-275 L/min at max. 380 barAutomatic speed control Air pressure control with pressure relief Pressure gauge

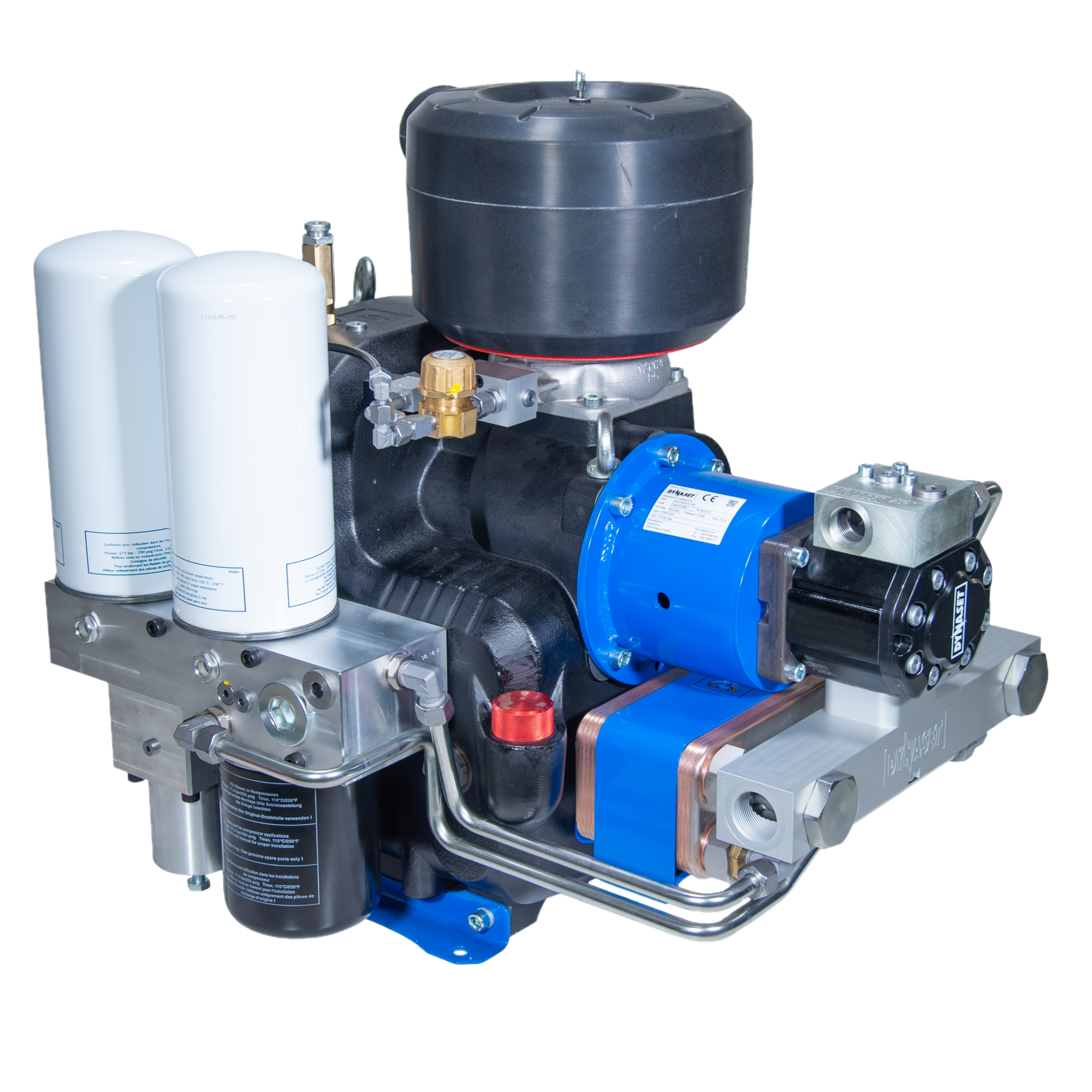

HKR1300/10-37

HKR1300 - Hydraulically driven compressed air screw compressor 1,300 L/min. at max. 8 bar (116 PSI) HKR1300/10-37

HKR1300/10-37

Efficiency: 1,300 L/min. at max. 10 BAR (145 PSI) Oil flow: 37 L/min at max. 230 BAR (Range: 27 up to max. 47 L/min.)HKR screw compressors are designed for continuous operation and can therefore be operated continuously. Options There are various additional options available for this compressor, allowing it to be used in all conditions and in all work environments. It is also available with an additional hose reel, which makes the unit even more flexible for mobile use. The compressed air hose is protected from damage by rolling up and can be stored to save space.Newly developed low-noise hydraulic motors The newly developed, low-noise hydraulic motors are integrated in the hydraulic HKR screw compressors. The compressors benefit in many ways. The biggest change is certainly the significantly reduced sound power level there. Not only does this make the engine noise more pleasurable for the ear, the frequency and structure of the sound have a far greater influence on the perception of sound, which have been significantly improved with the new engine and make it seem almost silent. High-frequency sound perceives the human ear as unpleasant and high sound amplitudes as painful. When developing the Dynaset motors, the sensitivity of the ear with regard to sound structure and frequency was taken into special account. The engine noise is perceived as much quieter and more pleasant and improves the working conditions and the user handling considerably. The quiet engines are also more efficient and durable. By reducing the friction occurring lower heat loss and less wear can be achieved. Also, the operating temperature drops. The new shaft seal on the engine is designed for higher pressures. DYNASET silent hydraulic motors are easy to identify due to their black finish and Dynaset logo The new DYNASET silent hydraulic motors offer the user clear advantages:Lower sound pressure level Lower frequency Pleasant sound structure Lower mechanical friction Increased efficiency Lower operating temperature Higher durability

HKR2000/13-68

HKR2000 - Hydraulically driven compressed air screw compressor 2,000 L/min. at max. 10 bar (145 PSI) HKR2000/13-68

HKR2000/13-68

Effective delivery rate: 2,000 L/min at 6 bar (87 PSI), max. 10 bar (145 PSI) Oil volume: 30-55 L/min at 205 bar (max. 230 bar) Automatic speed control Air pressure control with pressure relief Pressure gauge

HKR2000/10-53

HKR2000 - Hydraulically driven compressed air screw compressor 2,000 L/min. at max. 10 bar (145 PSI) HKR2000/10-53

HKR2000/10-53

Effective delivery rate: 2,000 L/min at 6 bar (87 PSI), max. 10 bar (145 PSI) Oil volume: 30-55 L/min at 205 bar (max. 230 bar) Automatic speed control Air pressure control with pressure relief Pressure gauge

HKR2500/10-67

HKR2500 - Hydraulically driven pneumatic screw compressor 2,500 L/min. at max. 10 bar (145 PSI) HKR2500/10-67

HKR2500/10-67

Effective delivery rate: 2,500 L/min at 6 bar (87 PSI), max. 10 bar (145 PSI) Oil volume: 35-80 L/min at 205 bar (max. 230 bar) Automatic speed control Air pressure regulation with pressure relief Pressure gauge

HKR4000/10-104

HKR4000 - Hydraulically driven compressed air screw compressor 4,000 L/min. at max. 10 bar (145 PSI) HKR4000/10-104

HKR4000/10-104

Effective delivery rate: 4,000 L/min at 6 bar (87 PSI), max. 10 bar (145 PSI) Oil volume: 55-105 L/min at 210 bar (max. 230 bar) Automatic speed control Air pressure control with pressure relief Pressure gauge

HKR4000/13-125

HKR4000 - Hydraulically driven compressed air screw compressor 4,000 L/min. at max. 10 bar (145 PSI) HKR4000/13-125

HKR4000/13-125

Effective delivery rate: 4,000 L/min at 6 bar (87 PSI), max. 10 bar (145 PSI) Oil volume: 55-105 L/min at 210 bar (max. 230 bar) Automatic speed control Air pressure control with pressure relief Pressure gauge

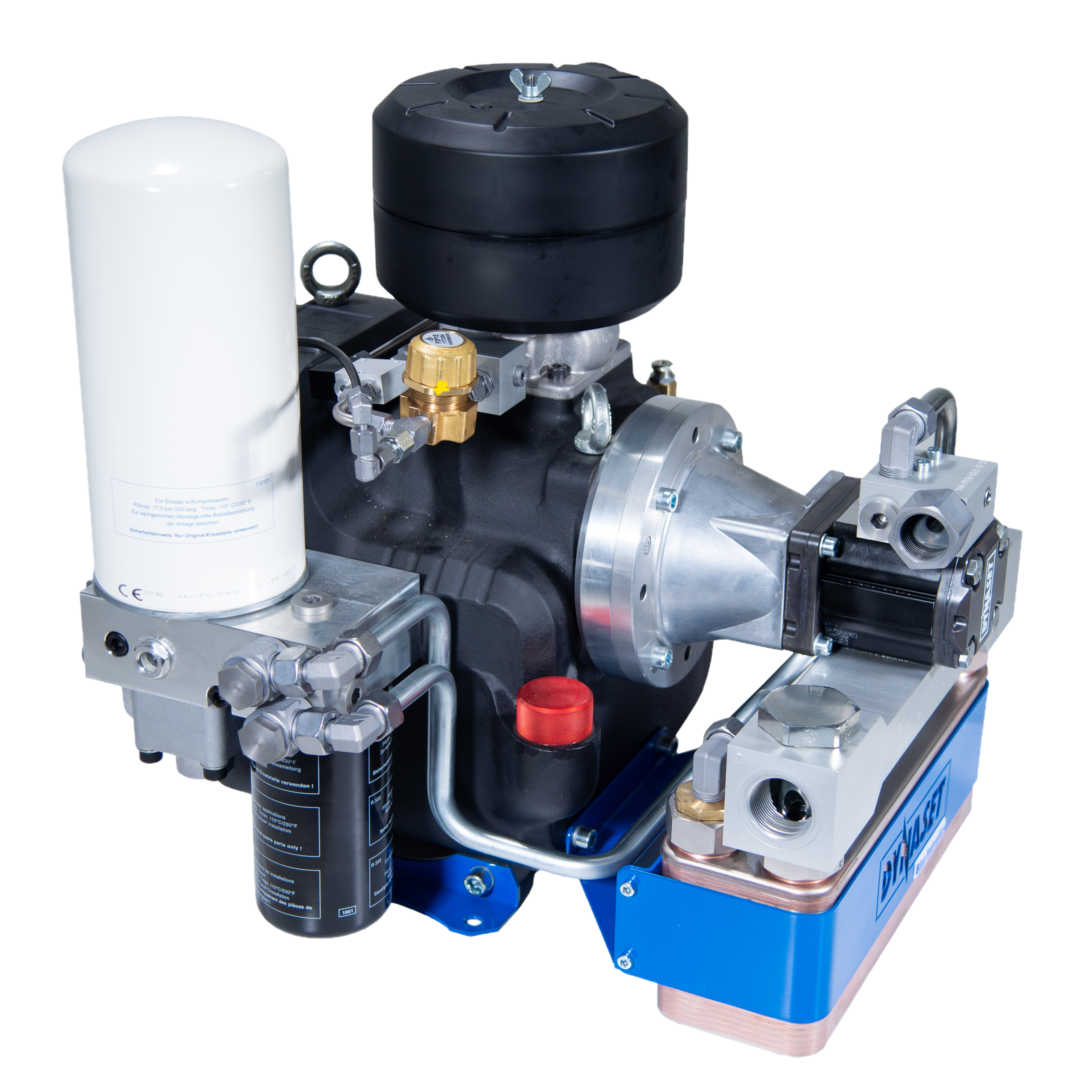

HKR500/10-29

HKR500 - Hydraulically driven air screw compressor 500 L/min. at max. 10 bar (145 PSI) HKR500/10-29

HKR500/10-29

Effective delivery rate: 500 L/min at 6 bar (87 PSI), max. 10 bar (145 PSI) Oil volume: 19-30 L/min at 123 bar (max. 230 bar) Automatic speed control Air pressure control with pressure relief Pressure gauge

HKR5000/10-137

HKR5000 - Hydraulically driven compressed air screw compressor 5,000 L/min. at max. 10 bar (145PSI) HKR5000/10-137

HKR5000/10-137

Effective delivery rate: 5,000 L/min at 6 bar (87 PSI), max. 10 bar (145 PSI) Oil volume: 60-140 L/min at 210 bar (max. 230 bar) Automatic speed control Air pressure control with pressure relief Pressure gauge Integrated air reservoir

HKR600/15-26

HKR600 - Hydraulically driven compressed air screw compressor 600 L/min. at max. 15 bar (218 PSI) HKR600/15-26

HKR600/15-26

Effective delivery rate: 600 L/min. at max. 15 bar (218 PSI) Oil volume: 26 L/min at max. 230 bar (Range: 27 to max. 47 L/min.)Automatic speed control Air pressure control with pressure relief Pressure gauge

HKR7500/10-183

HKR7500 - Hydraulically driven pneumatic screw compressor 7,500 L/min. at max. 10 bar (145 PSI) HKR7500/10-183

HKR7500/10-183

Effective delivery rate: 7,500 L/min at 6 bar (87 PSI), max. 10 bar (145 PSI) Oil volume: 70-200 L/min at 230 bar (max. 270 bar) Automatic speed control Air pressure control with pressure relief Pressure gauge

HKR6500/13-195

HKR7500 - Hydraulically driven pneumatic screw compressor 7,500 L/min. at max. 10 bar (145 PSI) HKR6500/13-195

HKR6500/13-195

Effective delivery rate: 7,500 L/min at 6 bar (87 PSI), max. 10 bar (145 PSI) Oil volume: 70-200 L/min at 230 bar (max. 270 bar) Automatic speed control Air pressure control with pressure relief Pressure gauge

HKR800/10-43

HKR800 - Hydraulically driven compressed air screw compressor 800 L/min. at max. 10 bar (145 PSI) HKR800/10-43

HKR800/10-43

Effective delivery rate: 800 L/min at 6 bar (87 PSI), max. 10 bar (145 PSI) Oil volume: 21-45 L/min 135 bar (max. 230 bar) Automatic speed control Air pressure control with pressure relief Pressure gauge

HRVB830-90

HRVB - Suction excavator attachment / Vacuum bucket HRVB830-90

HRVB830-90

Brand New DYNASET HRVB Hydraulic Recycling Vacuum Bucket Makes Waste Collecting Much Easier! DYNASET HRVB Hydraulic Recycling Vacuum Bucket is an excavator bucket that is specially designed to bring easiness to worksites’ cleaning and recycling tasks. This special bucket is a combination of an excavator bucket and a vacuum cleaner. On top of that, this bucket can also be used as an air blower.Especially in demolition sites, the smaller and lighter pieces of debris should be separated from the rubble piles because that way the waste treatment is much easier and cheaper. That is because commonly waste treatment is priced by weight. And why not use a regular bucket? With the HRVB less sand and rocks end up in the waste containers. So the waste container won’t include that much of a dead weight that consists of rocks and sand. Another way to do the sorting is by legwork, but that is a much slower way to do site cleaning than with an excavator with this bucket. In other words, using this bucket is much more cost-effective than traditional ways to collect waste.Fast Sorting During the Demolition With this bucket, it is fast to collect any types of wool, plastics, pieces of wood, and light expanded clay aggregate (LECA). It is even possible to collect specific materials during the demolition work. For example, the bucket can be used for collecting the wool from the structures right when they are exposed during the demolition. That way wool can be sorted before it ends up in rubble piles.For Daily Use on Worksites In construction sites, HRVB Hydraulic Recycling Vacuum Bucket can be used for daily clean up. Construction sites are often large areas and because of the wind, the packaging plastics and such try to spread to the environment. With the bucket, one excavator and operator can do the daily clean-up much faster than a bunch of workers. How Does It Work? First of all, the bucket can be equipped with a quick coupler so you can pick it up with your excavator. The hydraulics of the bucket includes four lines. Two of them are the pressure and tank lines, which transfer the hydraulic power to the hydraulic motor of the bucket which spins the fan blade. Because the hydraulic oil flow is powering up the operation of the bucket, the blade RPM, or power of the suction, is continuously adjustable via hydraulic oil flow. Two other lines are used for the hatch controls. This means that the operator can adjust the size of the suction port with the hatch.The bucket also has a port for an auxiliary vacuum hose. This port can be found from the backside of the bucket. This port can be used for vacuum cleaning that is done by legwork and a hose. So, if the cleaning task needs even more precise vacuum cleaning, the hose can be used for these tasks. The recommended diameter of this hose is 80-100 millimeters which ensure fast vacuum cleaning in tight places. For example, with the bucket’s auxiliary vacuum hose it is possible to empty stormwater drainages from the sand. So with this port, the user can do vacuum cleaning tasks which decreases the need for vacuum trucks in certain tasks like stormwater drainage emptying tasks. Air Blowing Ability As a Tool But what about the air blowing applications? The air blow port is on the same side as the auxiliary vacuum port. Basically, the air is blowing through this port all the time when the bucket’s fan is running. But if you want to use the bucket for air blowing you just need to flip the bucket with a rotator to another way around and you are ready to blow for example leaves, trash, and snow from your way. This application is in use at the tramway of Tampere, Finland as we speak. What Else Does the New Category Bring to The Table? The heart of the new product category, HFC Hydraulic Centrifugal Fan, can be a solution for many ventilation, air blow, and vacuum cleaning applications. Because the fan is driven by a hydraulic motor, it can be fitted into tight spaces. That’s because cooling of the unit is done by the air that flows through the unit.

KWDY-3-6,5-P13-PTO-GEAR-MB

KWDY - Strom-Druckluft für Ihr Fahrzeug, Strom für Mercedes Sprinter mit verstärktem Nebenantrieb (PTO+) KWDY-3-6,5-P13-PTO-GEAR-MB

KWDY-3-6,5-P13-PTO-GEAR-MB

Vehicle: Mercedes Sprinter 2 RWD + PTO ab 2018

Schraubenkompressor mit 1300 L/min. bei 10 bar (z. B. für Erdraketen)Stromgenerator 6,5 kVA (400/230 Volt)Anlage zum Einbau in Fahrzeuge mit verstärktem Nebenabtrieb (40 kW), beispielsweise VW CRAFTER, MAN TGE, MERCEDES SPRINTER, mit Ölkühler für den Nebenabtrieb* für erhöhte Dauerleistung.Der Motor Ihres Lieferwagens dient als Antrieb für diese Anlage. Ausstattung: 230 Volt / 14,2 A / CEE-Dose blau oder SCHUKO 400 Volt / 10 kVA / 9,4 A / CEE-Dose rot Druckluftkompressor, 1300 L/min. bei 10 bar Lieferumfang: Hydraulikpumpe mit Adapter für Nebenabtrieb Hinweis: Die Ölkühlung für den Nebenabtrieb muss beim Fahrzeughersteller bestellt werden!Strom-Generator,Druckluft-KompressorHydrauliköltank, Ölkühlung, Ölfilter,fahrzeugspezifische Kabeln und Adaptern Preis inklusive Einbau. (Schläuche, usw.)* Der Nebenabtrieb muss für den Anschluss einer Hydraulikpumpe vorbereitet sein; Vielzahnwelle.

KWF-E5-10-P6

KWF COMPACT AIR 650/10 - Generator-Kompressor-Einheit 230V/400V/12 bar für Werkstattfahrzeuge KWF-E5-10-P6

KWF-E5-10-P6

Komplettaggregat im Rahmen. Lieferung nur an Fachbetriebe.HYDRO COMPACT AIR 650/10 ist eine Aggregat zum Einbau in Service- und Werkstattfahrzeuge. Es kann in Fahrzeuge mit und ohne vorhandenen PTO-Nebenabtrieb* am Getriebe montiert werden.Der Motor Ihres Lieferwagens dient als Antrieb.Im Rahmen sind verbaut:Strom-Generator 10 kVA, je nach Einbauverhältnis liefert dieser Generator 5.000 bis 8.000 Watt (400 Volt)230 Volt / 5 kVA / 16 A / CEE-Dose blau oder SCHUKO400 Volt / 10 kVA / 16 A / CEE-Dose rotDruckluftkompressor, max. 650 L/min. bei max. 12 bar, mit 25 Liter Druckspeicher, Anschluss BSP1/2" IGHydrauliköltank, Ölkühlung, Ölfilter, Steuerventil, VerschlauchungSteuerung mit digitaler Anzeige der wichtigsten FunktionenLieferung ohne Anschlussschläuche* Der Nebenabtrieb muss für den Anschluss einer Hydraulikpumpe vorbereitet sein; Vielzahnwelle.

KWFE5-10-S30-P8-H-PTO-VW1

KWF-COMBY - Strom-Druckluft-Hydraulik-Schweißen für VW CRAFTER mit Nebenantrieb (PTO) bis 2016 KWFE5-10-S30-P8-H-PTO-VW1

KWFE5-10-S30-P8-H-PTO-VW1

Vehicle: VW Crafter 1 RWD + PTO bis 2016

HYDRO COMBY SW-F300 - PTO-GEAR ist eine Aggregat zum Einbau in Service- und Werkstattfahrzeuge.Es kann in Fahrzeuge mit Heckantrieb und vorhandenen PTO-Nebenabtrieb* am Getriebe montiert werden.Der Motor Ihres Lieferwagens dient als Antrieb für Generator, Kompressor und Hydraulikpumpe.Ausstattung:230 Volt / 5 kVA / 16 A / CEE-Dose blau oder SCHUKO 400 Volt / 10 kVA / 16 A / CEE-Dose rot 300 Ampere Elektroden-Schweißgerät mit Anschluss für Kabel-FernbedienungAnschluss für Schweißkabelstecker SK 35/50 Dorn Ø13mm(Schweißkabel-Set und Kabel-Fernbedienung im Lieferumfang nicht enthalten.)Druckluftkompressor, 1000 L/min. bei 12 bar, Anschluss BSP 1/2" IGHydraulikanschluss für externe Anwendungen, 20/30 L/min. bei 140 bar, FLATFACE-KupplungenLieferumfang:Hydraulikpumpe mit Adapter für PTO-AnschlussStrom-Generator-Einheit mit integriertem Schweißgerät mit Anschluss für Kabel-Fernbedienung.Schweißkabel-Set und Kabel-Fernbedienung im Lieferumfang nicht enthaltenDruckluft-Kompressor mit 25 Liter Druckspeicher, Anschluss BSP 1/2" InnengewindeLieferung ohne Druckluftschlauch und ZubehörHydrauliktank, Ölkühlung, FilterSteuerung mit fahrzeugspezifischen Kabeln und Adaptern Preis inklusive Einbau. (Schläuche, usw.)Für den Einbau in Ihr Fahrzeug muss das Fahrzeug bei uns angeliefert und abgeholt werden. Diese Transferkosten sind nicht enthalten.* Der Nebenabtrieb muss für den Anschluss einer Hydraulikpumpe vorbereitet sein; Vielzahnwelle.

Compressors, vacuum and fans: efficiency and performance for your applications.

Our product range, within compressors, vacuum and fans spans a wide range of tools that are at the heart of numerous industrial applications. Whether you are looking for piston compressors, screw compressors, vane compressors, blowers or vacuum pumps, we have the right solutions for your projects.

Piston compressors

Our DYNASET piston compressors convert hydraulic power into compressed air. Thus, DYNASET devices are designed for performance and reliability. They offer the ideal compressed air supply for mobile machines, vehicles or ships.

Screw compressors

For applications requiring continuous compressed air, our screw compressors are the optimal choice. Whether for service vehicles, construction machinery or for pneumatic applications in general, screw compressors are the perfect solution for demanding tasks due to their high efficiency and low maintenance requirements.

Vane compressors

Our vane compressors are compact and powerful. The advantage of these units is that despite their size, they provide equivalent performance to compressors on a trailer. This makes them ideal for mobile applications, e.g. mining machines, drilling rigs or even excavators.

Blowers/Fans

Whether in industrial processes or in the field of air-conditioning technology - our blowers and fans meet the highest demands in terms of performance and quality.

Vacuum pumps/suction dredgers

Our vacuum pumps and suction dredgers are the right choice for applications where vacuum or suction power is required. They are robust, powerful and can be used in various industries. In all the above products, the equipment gets its drive power from hydraulics. Whether you need compressed air, vacuum or air movement, we offer the right tools and solutions for your requirements.