Railway engineering

Für alle Arten von Bahntechnik bieten wir Ihnen eine Vielzahl an hydraulischen Werkzeugen. Besuchen Sie noch heute unser Website!

- Areas of application

- Tools for electric power distribution

- Hydraulic power packs

- Attachments for construction, agricultural and municipal machinery

- Hydraulics for commercial vehicles / vans

- Steel construction

- Recycling / Demolition

- Construction industry

- Rescue technology

- Forestry and landscaping / horticulture

- Underwater tools / diving tools

- Pipe construction

- Wind energy / wind turbines

- Solar energy / solar power plants

- Railway engineering

- Available

- Delivery Time : 3-4 weeks

Brand New DYNASET HRVB Hydraulic Recycling Vacuum Bucket Makes Waste Collecting Much Easier! DYNASET HRVB Hydraulic Recycling Vacuum Bucket is an excavator bucket that is specially designed to bring easiness to worksites’ cleaning and recycling tasks. This special bucket is a combination of an excavator bucket and a vacuum cleaner. On top of that, this bucket can also be used as an air blower.Especially in demolition sites, the smaller and lighter pieces of debris should be separated from the rubble piles because that way the waste treatment is much easier and cheaper. That is because commonly waste treatment is priced by weight. And why not use a regular bucket? With the HRVB less sand and rocks end up in the waste containers. So the waste container won’t include that much of a dead weight that consists of rocks and sand. Another way to do the sorting is by legwork, but that is a much slower way to do site cleaning than with an excavator with this bucket. In other words, using this bucket is much more cost-effective than traditional ways to collect waste.Fast Sorting During the Demolition With this bucket, it is fast to collect any types of wool, plastics, pieces of wood, and light expanded clay aggregate (LECA). It is even possible to collect specific materials during the demolition work. For example, the bucket can be used for collecting the wool from the structures right when they are exposed during the demolition. That way wool can be sorted before it ends up in rubble piles.For Daily Use on Worksites In construction sites, HRVB Hydraulic Recycling Vacuum Bucket can be used for daily clean up. Construction sites are often large areas and because of the wind, the packaging plastics and such try to spread to the environment. With the bucket, one excavator and operator can do the daily clean-up much faster than a bunch of workers. How Does It Work? First of all, the bucket can be equipped with a quick coupler so you can pick it up with your excavator. The hydraulics of the bucket includes four lines. Two of them are the pressure and tank lines, which transfer the hydraulic power to the hydraulic motor of the bucket which spins the fan blade. Because the hydraulic oil flow is powering up the operation of the bucket, the blade RPM, or power of the suction, is continuously adjustable via hydraulic oil flow. Two other lines are used for the hatch controls. This means that the operator can adjust the size of the suction port with the hatch.The bucket also has a port for an auxiliary vacuum hose. This port can be found from the backside of the bucket. This port can be used for vacuum cleaning that is done by legwork and a hose. So, if the cleaning task needs even more precise vacuum cleaning, the hose can be used for these tasks. The recommended diameter of this hose is 80-100 millimeters which ensure fast vacuum cleaning in tight places. For example, with the bucket’s auxiliary vacuum hose it is possible to empty stormwater drainages from the sand. So with this port, the user can do vacuum cleaning tasks which decreases the need for vacuum trucks in certain tasks like stormwater drainage emptying tasks. Air Blowing Ability As a Tool But what about the air blowing applications? The air blow port is on the same side as the auxiliary vacuum port. Basically, the air is blowing through this port all the time when the bucket’s fan is running. But if you want to use the bucket for air blowing you just need to flip the bucket with a rotator to another way around and you are ready to blow for example leaves, trash, and snow from your way. This application is in use at the tramway of Tampere, Finland as we speak. What Else Does the New Category Bring to The Table? The heart of the new product category, HFC Hydraulic Centrifugal Fan, can be a solution for many ventilation, air blow, and vacuum cleaning applications. Because the fan is driven by a hydraulic motor, it can be fitted into tight spaces. That’s because cooling of the unit is done by the air that flows through the unit.

- Available

- Delivery Time : 3-4 weeks

- Available

- Delivery Time : 1-2 weeks

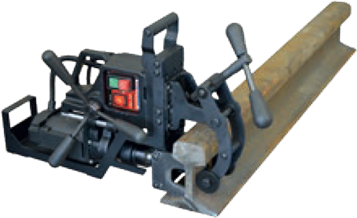

Motor: HONDA GXH50, 49,4 cm³, 1500 WBohreraufnahme: Ø 19 mm (3/4" Weldon)Maximaler Bohrdurchmesser mit Kernlochbohrer: Ø 36 mmMaximaler Bohrdurchmesser mit Spiralbohrer: Ø 16 mmMaximale Bohrtiefe: 30 mmHub: 39 mmDrehzahl ohne Last: 120-280 min-1Drehzahl mit Last: 225 min-1Erforderliche Umgebungstemperatur: -5°C bis +40°CGewicht: 18,7 kg

- Available

- Delivery Time : 1-2 weeks

- Available

- Delivery Time : 1-2 weeks

Motor: Elektromotor, 2000 WBohreraufnahme: Ø 19 mm (3/4" Weldon)Maximaler Bohrdurchmesser mit Kernlochbohrer: Ø 38 mmMaximaler Bohrdurchmesser mit Spiralbohrer: Ø 19 mmMaximale Bohrtiefe: mmHub: mmDrehzahl ohne Last: 370 min-1Drehzahl mit Last: min-1Erforderliche Umgebungstemperatur: -5°C bis +40°CGewicht: 18 kgSBM-DP3AC-2 = mit SchnellspannerSBM-DP3AC-2S = mit überfahrbarer Schienenklammer

- Available

- Delivery Time : 1-2 weeks

- Available

- Delivery Time : 1-2 weeks

Motor: akkubetriebener ElektromotorBohreraufnahme: Ø 19 mm (3/4" Weldon)Maximaler Bohrdurchmesser mit Kernlochbohrer: Ø 38 mmMaximaler Bohrdurchmesser mit Spiralbohrer: Ø 16 mmMaximale Bohrtiefe: Hub: Drehzahl ohne Last: min-1Drehzahl mit Last: min-1Erforderliche Umgebungstemperatur: -5°C bis +40°CGewicht: 20 kg

- Available

- Delivery Time : 1-2 weeks

- Available

- Delivery Time : 1-2 weeks

Motor: ElektromotorBohreraufnahme: Ø 19 mm (3/4" Weldon)Maximaler Bohrdurchmesser mit Kernlochbohrer: Ø 36 mmMaximaler Bohrdurchmesser mit Spiralbohrer: Ø 16 mmMaximale Bohrtiefe: Hub: Drehzahl ohne Last: min-1Drehzahl mit Last: min-1Erforderliche Umgebungstemperatur: -5°C bis +40°CGewicht: 19,7 kg

- Available

- Delivery Time : 1-2 weeks

- Available

- Delivery Time : 1-2 weeks

Motor: 230 Volt, 1500 WBohreraufnahme: Ø 19 mm (3/4" Weldon)Maximaler Bohrdurchmesser mit Kernlochbohrer: Ø 36 mmMaximaler Bohrdurchmesser mit Spiralbohrer: Ø 16 mmMaximale Bohrtiefe: 30 mmHub: 40 mmDrehzahl ohne Last: 500 min-1Drehzahl mit Last: 350 min-1Erforderliche Umgebungstemperatur: -5°C bis +40°CGewicht: 14,5 kg

- Available

- Delivery Time : 1-2 weeks

- No longer available

- Delivery Time : 3-4 weeks

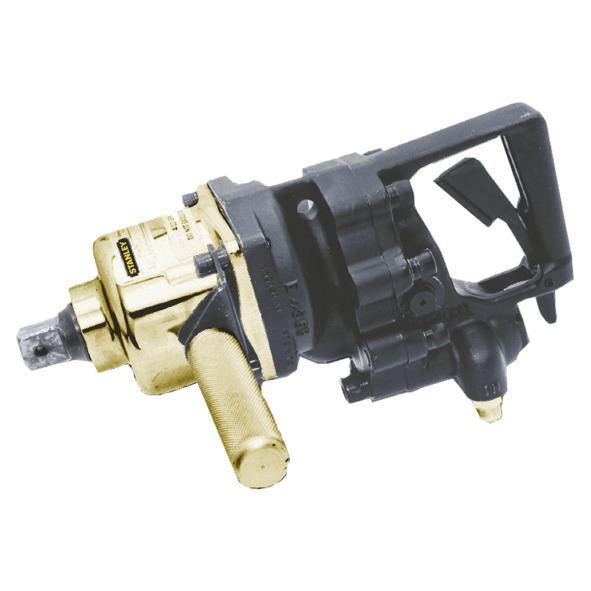

The STANLEY® impact wrench ID-07 develops a torque of up to 675 Nm, which makes it the ideal tool for drilling holes from 12 to 27 mm in diameter. No torque effect on the user Right / left rotation Large switch for easy operation even when wearing work gloves Standard version

- No longer available

- Delivery Time : 3-4 weeks

- No longer available

- Delivery Time : 3-4 weeks

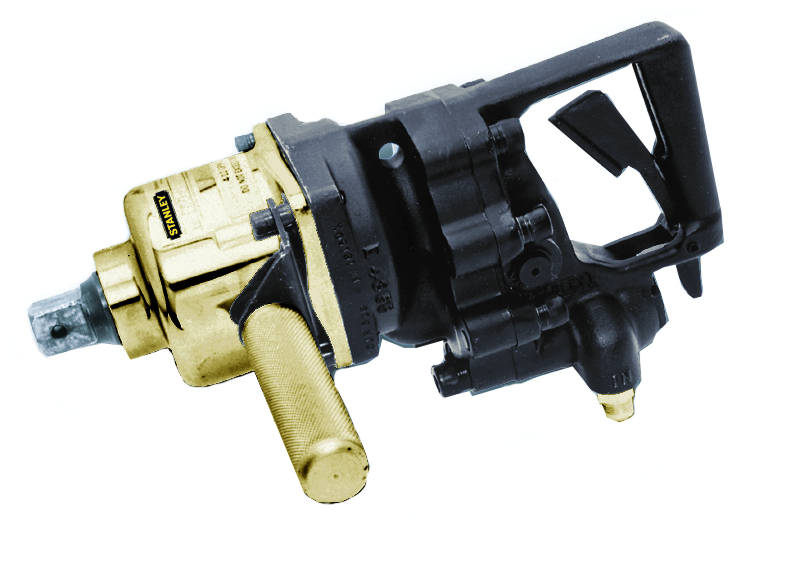

The STANLEY® impact wrench IW-12 develops a torque of up to 1632 Nm. The IW-12 is used as a thread nut, bolt and anchor bolt driver and is also suitable for drilling holes in wood. No torque effect on the user Adjustable pressure, oil flow rate, 70-140 bar working pressure Right / left rotation Large switch also for operation with work gloves

- No longer available

- Delivery Time : 3-4 weeks

- No longer available

- Delivery Time : 3-4 weeks

The STANLEY® impact screw IW-16 develops a torque of up to 3400 Nm. The IW-16 is used as a nut, bolt, anchor bolt driver and other heavy duty media. No torque effect on the user Adjustable pressure strength Right / left rotation Large "D" handle also for use with work gloves Template grab handle

- No longer available

- Delivery Time : 3-4 weeks

- No longer available

- Delivery Time : 3-4 weeks

The STANLEY® impact screw IW-16 develops a torque of up to 3400 Nm. The IW-16 is used as a nut, bolt, anchor bolt driver and other heavy duty media. No torque effect on the user Adjustable pressure strength Right / left rotation Large "D" handle also for use with work gloves Template grab handle Underwater version for diving work

- No longer available

- Delivery Time : 3-4 weeks

- No longer available

- Delivery Time : 3-4 weeks

The STANLEY® impact screw IW-16 develops a torque of up to 3400 Nm. The IW-16 is used as a nut, bolt, anchor bolt driver and other heavy duty media. No torque effect on the user Adjustable pressure strength Right / left rotation Large "D" handle also for use with work gloves Template grab handle Underwater version for diving work

- No longer available

- Delivery Time : 3-4 weeks

- No longer available

- Delivery Time : 3-4 weeks

The STANLEY® impact screw IW-16 develops a torque of up to 3400 Nm. The IW-16 is used as a nut, bolt, anchor bolt driver and other heavy duty media. No torque effect on the user Adjustable pressure strength Right / left rotation Large "D" handle also for use with work gloves Template grab handle Underwater version for diving work

- No longer available

- Delivery Time : 3-4 weeks

- No longer available

- Delivery Time : 3-4 weeks

The STANLEY® impact screw IW-16 develops a torque of up to 3400 Nm. The IW-16 is used as a nut, bolt, anchor bolt driver and other heavy duty media. No torque effect on the user Adjustable pressure strength Right / left rotation Large "D" handle also for use with work gloves Template grab handle Underwater version for diving work

- No longer available

- Delivery Time : 3-4 weeks

- No longer available

- Delivery Time : 3-4 weeks

The STANLEY® impact screw IW-16 develops a torque of up to 3400 Nm. The IW-16 is used as a nut, bolt, anchor bolt driver and other heavy duty media. No torque effect on the user Adjustable pressure strength Right / left rotation Large "D" handle also for use with work gloves Template grab handle Underwater version for diving work

- No longer available

- Delivery Time : 3-4 weeks

For years we have been involved in the development of innovative solutions for track, catenary and signal construction.

We have set trends with compact rail drilling machines, rail contacts that can be used on both sides and compact hydraulic power units.

We are currently supplying the first 230 kN cordless press to use the existing 60 mm press inserts (PFISTERER size III).

Our battery pump with GPS position detection for documentation of the workplace is unique on the market. (Distribution via GOLDSCHIDT-ELEKTROTHERMIT).

In addition to our own products, we offer products from:

- STANLEY Infrastructure

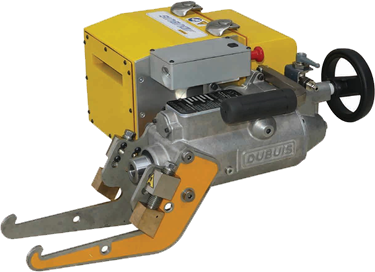

- STANLEY DUBUIS

- DOA