Kompressoren

Filter

–

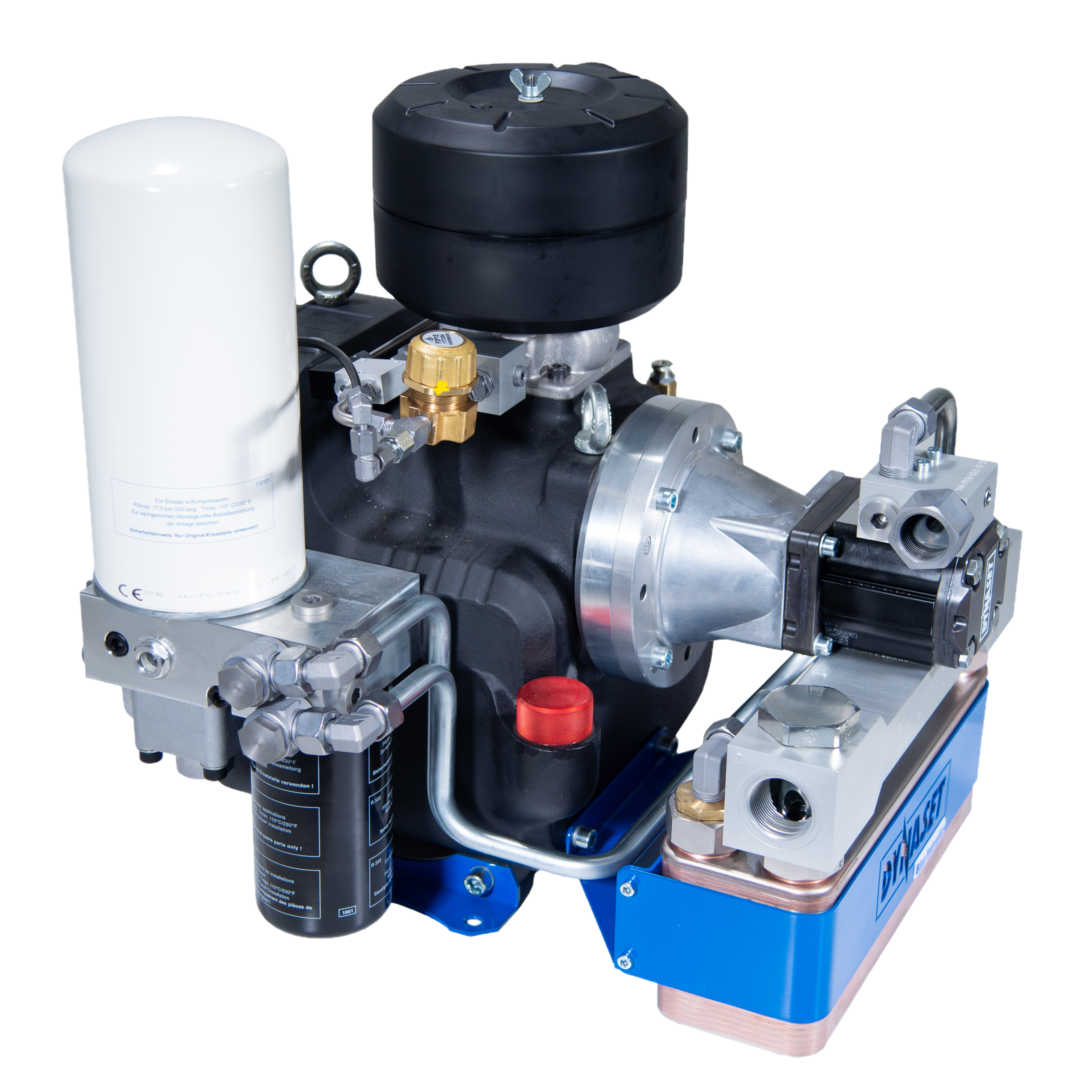

HK1000 - Hydraulically driven pneumatic piston compressor 1,000 L/min. at max. 12 bar (174 PSI)

Flow rate eff .: 1,000 L/min. at max. 12 BAR (174 PSI) Oil flow (input): 35 L/min. at max. 230 BAR (Flow: 12 up to max. 50 L/min.)Integrated accumulator: 14 litersThe engine is connected directly to the crankshaft of the piston unit for robust power transfer and maximum efficiency. The movement of the piston directs compressed air to the frame tank, from where it can be removed directly for pneumatic applications. It is a compact, easy to install compressor unit for the mobile supply of compressed air devices. The HK compressor is ideal for mobile use on drills, tractors and excavators.Options There are various additional options available for this compressor, allowing it to be used in all conditions and in all work environments. It is also available with an additional hose reel, which makes the unit even more flexible for mobile use. The compressed air hose is protected from damage by rolling up and can be stored to save space.

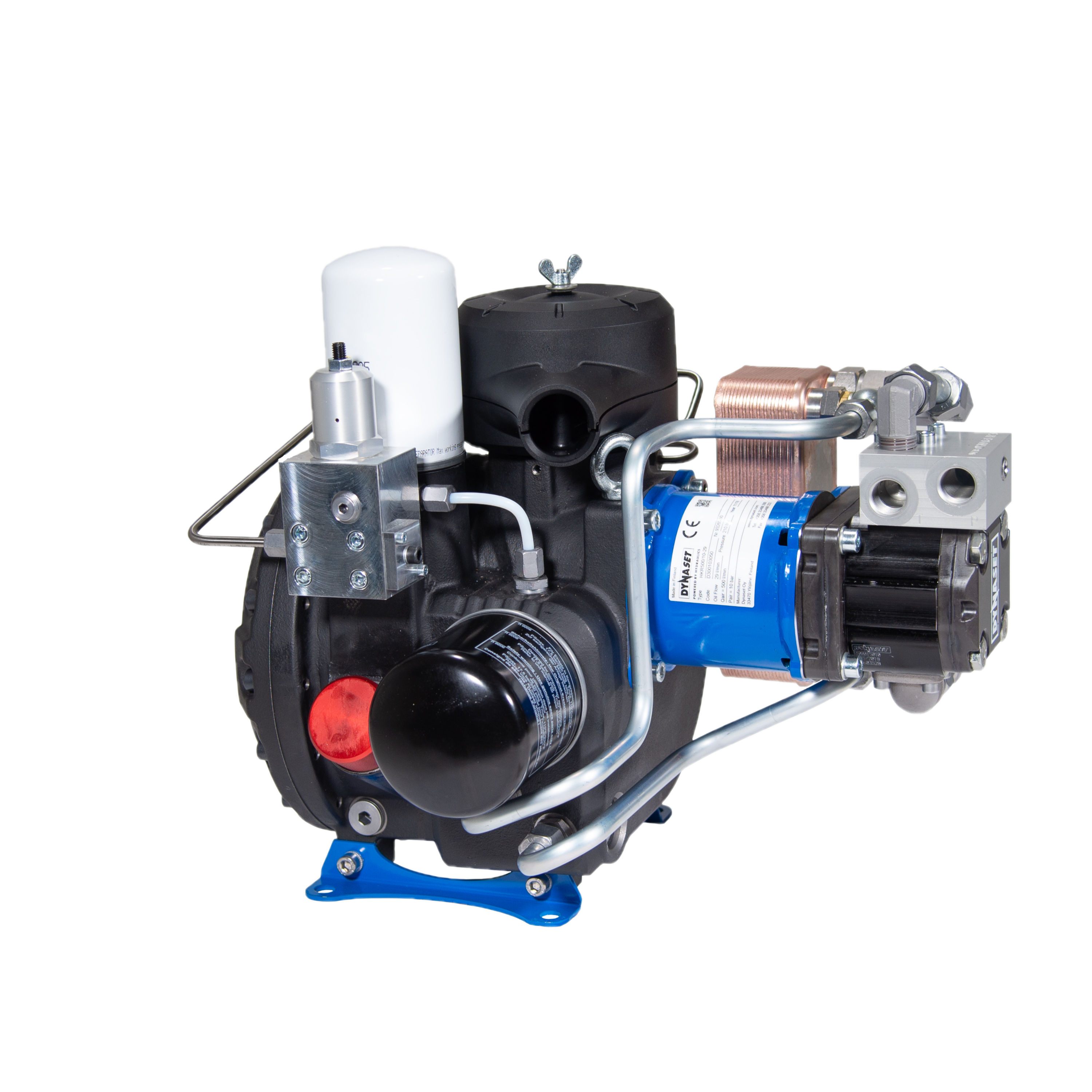

HK450 - Hydraulically driven pneumatic piston compressor 450 L/min. at max. 8 bar (116 PSI)

Flow rate eff .: 450 L/min. at max. 8 BAR (116 PSI) (Special version with max. 10 BAR available)Oil flow (input): 15 L/min. at max. 210 BAR (Range: 10 up to max. 35 L/min.)Integrated accumulator: 4 litersThe engine is connected directly to the crankshaft of the piston unit for robust power transfer and maximum efficiency. The movement of the piston directs compressed air to the frame tank, from where it can be removed directly for pneumatic applications. Thanks to these integrated tanks, no additional space is needed for compressed air storage. It is a compact, easy to install compressor unit for the mobile supply of compressed air devices. The HK compressor is ideal for mobile use on drills, tractors and excavators.Options There are various additional options available for this compressor, allowing it to be used in all conditions and in all work environments. It is also available with an additional hose reel, which makes the unit even more flexible for mobile use. The compressed air hose is protected from damage by rolling up and can be stored to save space.

HKR11000 - Hydraulically driven pneumatic screw compressor 11,000 L/min. at max. 10 bar (145 PSI)

Effective delivery rate: 11,000 L/min at 6 bar (87 PSI), max. 10 bar (145 PSI) Oil quantity: 165-275 L/min at max. 380 barAutomatic speed control Air pressure control with pressure relief Pressure gauge

HKR11000 - Hydraulically driven pneumatic screw compressor 11,000 L/min. at max. 10 bar (145 PSI)

Effective delivery rate: 11,000 L/min at 6 bar (87 PSI), max. 10 bar (145 PSI) Oil quantity: 165-275 L/min at max. 380 barAutomatic speed control Air pressure control with pressure relief Pressure gauge

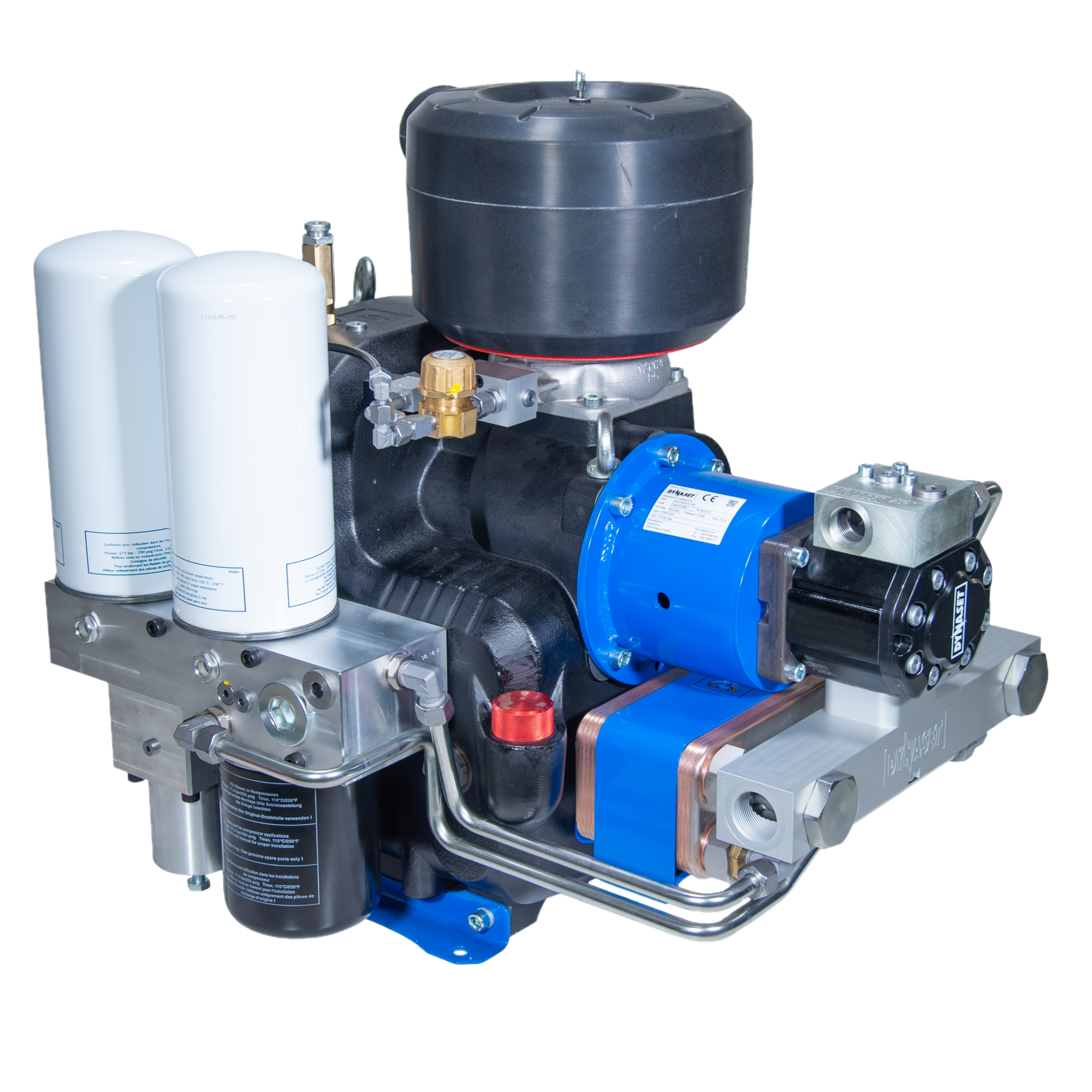

HKR1300 - Hydraulically driven compressed air screw compressor 1,300 L/min. at max. 8 bar (116 PSI)

Efficiency: 1,300 L/min. at max. 10 BAR (145 PSI) Oil flow: 37 L/min at max. 230 BAR (Range: 27 up to max. 47 L/min.)HKR screw compressors are designed for continuous operation and can therefore be operated continuously. Options There are various additional options available for this compressor, allowing it to be used in all conditions and in all work environments. It is also available with an additional hose reel, which makes the unit even more flexible for mobile use. The compressed air hose is protected from damage by rolling up and can be stored to save space.Newly developed low-noise hydraulic motors The newly developed, low-noise hydraulic motors are integrated in the hydraulic HKR screw compressors. The compressors benefit in many ways. The biggest change is certainly the significantly reduced sound power level there. Not only does this make the engine noise more pleasurable for the ear, the frequency and structure of the sound have a far greater influence on the perception of sound, which have been significantly improved with the new engine and make it seem almost silent. High-frequency sound perceives the human ear as unpleasant and high sound amplitudes as painful. When developing the Dynaset motors, the sensitivity of the ear with regard to sound structure and frequency was taken into special account. The engine noise is perceived as much quieter and more pleasant and improves the working conditions and the user handling considerably. The quiet engines are also more efficient and durable. By reducing the friction occurring lower heat loss and less wear can be achieved. Also, the operating temperature drops. The new shaft seal on the engine is designed for higher pressures. DYNASET silent hydraulic motors are easy to identify due to their black finish and Dynaset logo The new DYNASET silent hydraulic motors offer the user clear advantages:Lower sound pressure level Lower frequency Pleasant sound structure Lower mechanical friction Increased efficiency Lower operating temperature Higher durability

HKR2000 - Hydraulically driven compressed air screw compressor 2,000 L/min. at max. 10 bar (145 PSI)

Effective delivery rate: 2,000 L/min at 6 bar (87 PSI), max. 10 bar (145 PSI) Oil volume: 30-55 L/min at 205 bar (max. 230 bar) Automatic speed control Air pressure control with pressure relief Pressure gauge

HKR2000 - Hydraulically driven compressed air screw compressor 2,000 L/min. at max. 10 bar (145 PSI)

Effective delivery rate: 2,000 L/min at 6 bar (87 PSI), max. 10 bar (145 PSI) Oil volume: 30-55 L/min at 205 bar (max. 230 bar) Automatic speed control Air pressure control with pressure relief Pressure gauge

HKR2500 - Hydraulically driven pneumatic screw compressor 2,500 L/min. at max. 10 bar (145 PSI)

Effective delivery rate: 2,500 L/min at 6 bar (87 PSI), max. 10 bar (145 PSI) Oil volume: 35-80 L/min at 205 bar (max. 230 bar) Automatic speed control Air pressure regulation with pressure relief Pressure gauge

HKR4000 - Hydraulically driven compressed air screw compressor 4,000 L/min. at max. 10 bar (145 PSI)

Effective delivery rate: 4,000 L/min at 6 bar (87 PSI), max. 10 bar (145 PSI) Oil volume: 55-105 L/min at 210 bar (max. 230 bar) Automatic speed control Air pressure control with pressure relief Pressure gauge

HKR4000 - Hydraulically driven compressed air screw compressor 4,000 L/min. at max. 10 bar (145 PSI)

Effective delivery rate: 4,000 L/min at 6 bar (87 PSI), max. 10 bar (145 PSI) Oil volume: 55-105 L/min at 210 bar (max. 230 bar) Automatic speed control Air pressure control with pressure relief Pressure gauge

HKR500 - Hydraulically driven air screw compressor 500 L/min. at max. 10 bar (145 PSI)

Effective delivery rate: 500 L/min at 6 bar (87 PSI), max. 10 bar (145 PSI) Oil volume: 19-30 L/min at 123 bar (max. 230 bar) Automatic speed control Air pressure control with pressure relief Pressure gauge

HKR5000 - Hydraulically driven compressed air screw compressor 5,000 L/min. at max. 10 bar (145PSI)

Effective delivery rate: 5,000 L/min at 6 bar (87 PSI), max. 10 bar (145 PSI) Oil volume: 60-140 L/min at 210 bar (max. 230 bar) Automatic speed control Air pressure control with pressure relief Pressure gauge Integrated air reservoir

HKR600 - Hydraulically driven compressed air screw compressor 600 L/min. at max. 15 bar (218 PSI)

Effective delivery rate: 600 L/min. at max. 15 bar (218 PSI) Oil volume: 26 L/min at max. 230 bar (Range: 27 to max. 47 L/min.)Automatic speed control Air pressure control with pressure relief Pressure gauge

HKR7500 - Hydraulically driven pneumatic screw compressor 7,500 L/min. at max. 10 bar (145 PSI)

Effective delivery rate: 7,500 L/min at 6 bar (87 PSI), max. 10 bar (145 PSI) Oil volume: 70-200 L/min at 230 bar (max. 270 bar) Automatic speed control Air pressure control with pressure relief Pressure gauge

HKR7500 - Hydraulically driven pneumatic screw compressor 7,500 L/min. at max. 10 bar (145 PSI)

Effective delivery rate: 7,500 L/min at 6 bar (87 PSI), max. 10 bar (145 PSI) Oil volume: 70-200 L/min at 230 bar (max. 270 bar) Automatic speed control Air pressure control with pressure relief Pressure gauge

HKR800 - Hydraulically driven compressed air screw compressor 800 L/min. at max. 10 bar (145 PSI)

Effective delivery rate: 800 L/min at 6 bar (87 PSI), max. 10 bar (145 PSI) Oil volume: 21-45 L/min 135 bar (max. 230 bar) Automatic speed control Air pressure control with pressure relief Pressure gauge

Druckluft kann als Energiequelle oder Blasluft genutzt werden. Dynaset Hydraulikkompressoren wandeln die Hydraulikleistung mobiler Maschinen, Fahrzeuge oder Schiffe für die Drucklufterzeugung um. Die Kompressoren können für Druckluftwerkzeuge und viele weitere Anwendungen im mobilen Bereich genutzt werden.

Hydraulikkompressoren nutzen die Hydraulik zur Erzeugung von Druckluft. Dank ihrer extrem kompakten Abmessungen und des geringen Gewichts lassen sie sich problemlos in mobile Maschinen, Fahrzeuge oder Schiffe einbauen. Ein Hydraulikkompressor an Bord ist immer einsatzbereit und ermöglicht dadurch effizientes Arbeiten.

Vorteile von Hydraulikkompressoren

- Immer an Bord und einsatzbereit

- Geeignet für eine Vielzahl von Anwendungen

- Zuverlässiger 24/7-Betrieb

- Zeit-, platz- und ressourcensparende Technologie

- Umweltfreundlich